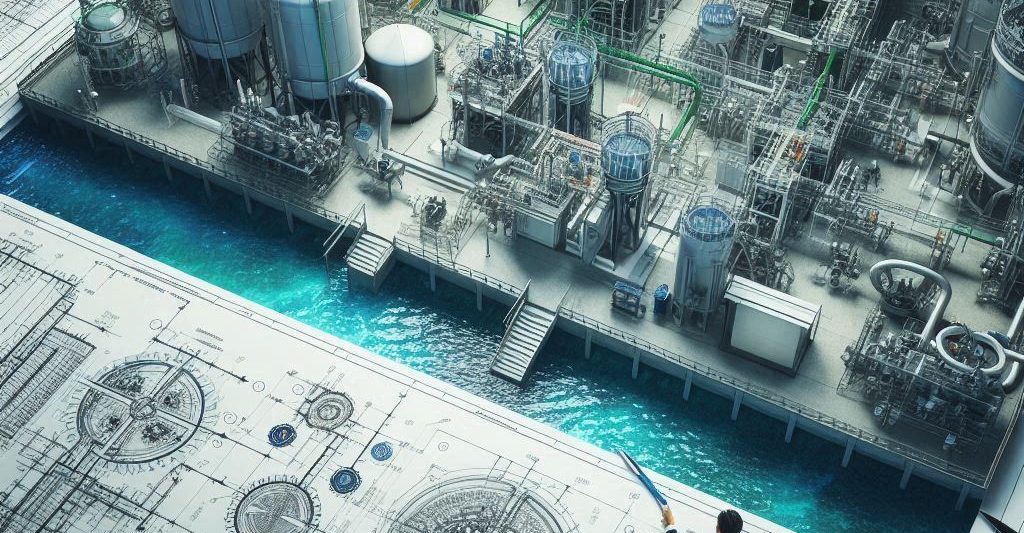

Custom Design Services for Industrial Wastewater Treatment Plants

Finding the perfect solution for treating wastewater from industrial processes can feel overwhelming. But it doesn’t have to be. This is where Custom design services for industrial wastewater treatment plants can make a real difference. These services offer specialized expertise, working with you to create or retrofit your existing wastewater treatment system tailored to your specific needs and regulations.

Whether you’re in food processing, energy or manufacturing understanding these treatment process optimization services can help you make informed choices for your industrial company and the environment.

Custom design services for industrial wastewater treatment plants are all utilizing the most efficient, effective, and sustainable solutions. This means moving away from a one-size-fits-all approach and looking closely at the specific characteristics of your water treatment systems operation.

The goal is to optimize your treatment facilities to ensure that you are seamlessly tackling your specific challenges, while optimizing cost and meet ever stricter regulatory requirements and sustainability goals.

Table of Contents:

- Why Consider a Custom Designed Wastewater Treatment System?

- How Does The Custom Design Process Work?

- Conclusion

- FAQs about Custom Design Services For Industrial Wastewater Treatment Plants

Why Consider a Custom Designed Wastewater Treatment System?

Generic, off-the-shelf solutions might be tempting because they seem simpler at first glance. But they often lead to headaches down the road. This is especially true when it comes to something as critical as industrial wastewater treatment. Custom modular systems for wastewater treatment provide flexibility and efficiency.

Think of it like this, every industry produces a distinct type of wastewater with its own mix of contaminants. A food processing plant, for instance, deals with organic materials, while a metal finishing facility contends with heavy metals. A pre-packaged wastewater treatment plant might struggle to effectively treat these specific contaminants.

Addressing Specific Needs and Challenges

When you go with Custom design services to retrofit existing systems or to build new industrial wastewater treatment plants, you’re essentially bringing in experts.

They look at things like the volume of wastewater you produce, the kinds of contaminants you need to remove, the layout of your facility, and of course, your budget. They consider factors like storm water management and the possibility of greywater recycling.

Custom-designed systems often incorporate dissolved air flotation or lamella clarification systems for efficient solids removal in wastewater industrial processes.

The experts at Genesis Water Technologies will help you find innovative solutions that can even save you money in the long run. The goal is to design and integrate effective sustainable treatment solutions to meet your specific needs.

Meeting Regulatory Standards with Confidence

Navigating environmental regulations is a big part of running any industrial operation. Different regions have unique standards that your facility needs to meet. Custom design services ensure that your wastewater treatment plant complies with all relevant regulations while also meeting your sustainability goals.

These design services assist you in stay up-to-date on the latest local, state, and federal requirements and incorporate them directly into the design. Genesis Water Technologies understands the complexities of treatment systems and can guide you through the permitting process. We can also advise on best practices for operational services, helping you stay compliant.

Ensuring Long-term Operational Efficiency

You’re not just investing in a wastewater treatment plant, you’re investing in a solution that works reliably for years to come. A custom designed or retrofitted design projects are built to maximize efficiency, minimize operational costs, and seamlessly integrate into your facility’s workflow.

Custom-designed modular treatment systems also allow for modifications and expansions in the future, adapting to your growing needs. This flexibility is crucial as your business evolves.

How Does The Custom Design Process Work?

When you partner with a provider of custom design services for industrial wastewater treatment plants, they’ll usually follow a structured process to get everything just right. This complete water optimization approach allows us to carefully evaluate your specific needs and integrate a suitable treatment solution for your industrial company.

1. Site Assessment and Data Collection

The journey starts with a comprehensive assessment of your site. This involves gathering crucial information about your facility’s wastewater output, such as the average and peak flow rates, the physical and chemical characteristics of your wastewater, the available space for the treatment plant to be retrofitted or implemented, and the layout of your facility’s utilities and infrastructure.

By gathering detailed data right from the start, a clear understanding of your situation is developed. It’s during this step that you can also discuss your long-term goals for your operation. That way, the sustainable treatment approach can be determined with those goals in mind.

2. Treatability Testing

This step focuses on figuring out how treatable your wastewater is. Treatability studies use small-scale simulations of the treatment processes they plan to implement in the final design. These simulations help identify and validate an optimal treatment approach to handle your specific water contaminants. As a result of this testing, the process is fine-tuned, making adjustments based on the characteristics of your wastewater and the treatment goals.

3. Conceptual Design Development

This stage brings the project to life visually and technically. Armed with the knowledge gathered from the previous stages, our team develops conceptual designs to retrofit or create your wastewater treatment plant configuration. This includes developing process flow diagrams that detail the different treatment stages.

Following this, preliminary layout plans with equipment arrangements are created that fit into the designated space various. The conceptual process design is presented for your review and approval. Any modifications you need or preferences you have can be incorporated before moving forward.

4. Detailed Engineering Design

Once the conceptual design gets your green light, the process moves into the detailed engineering. This is where the finer points get hammered out. It includes preparing detailed equipment specifications. This means choosing the specific technologies to be utilized like, Zeoturb liquid bio organic flocculant, G-CAT catalytic activation technology, specialized electrocoagulation, membrane systems, pumps, pipes, valves, aeration systems, and monitoring instruments.

Our engineers create blueprints that accurately define every element. Structural modular designs ensure the physical foundation is safe, functional, and compliant.

5. Construction and Commissioning

Now it’s time to implement the wastewater treatment design. Experienced project managers are often on board. They supervise every part of construction. These project managers ensure the project stays on schedule, meets all quality and safety standards, and follows the approved design precisely.

Testing of all systems and components happens. The team makes sure every piece of the system works as it should and adjusts any settings if needed. It’s essentially making sure everything works smoothly.

Conclusion

Investing in custom design services for industrial wastewater treatment plants is a strategic move toward operational excellence and environmental stewardship. By opting for a tailored wastewater treatment system, you address your facility’s unique challenges with precision, ensuring compliance with stringent regulatory standards, meeting sustainability goals and achieving long-term cost efficiency.

Custom-designed solutions not only enhance the effectiveness of your treatment processes but also provide the flexibility to adapt to future growth and evolving industry demands.

Don’t settle for one-size-fits-all solutions that may fall short of your operational needs. Embrace a custom-designed approach to optimize your wastewater treatment facilities. By partnering with experts like Genesis Water Technologies, you can implement innovative and sustainable treatment solutions that align with your specific goals.

Take the first step toward a more efficient and eco-friendly operation today. To explore how custom design services can transform your industrial wastewater management contact the water treatment specialists at Genesis Water Technologies today at +1 321 280 2742 or via email at customersupport@genesiswatertech.com.

Together, let’s pave the way for a sustainable and reliable clean water supply today!

FAQs about Custom Design Services For Industrial Wastewater Treatment Plants

How would you design a wastewater treatment plant?

Designing a wastewater treatment plant is a multi-faceted process that hinges on carefully evaluating the nature of the wastewater and the regulatory standards that must be met. A critical initial step is analyzing the wastewater, identifying the contaminants, and determining the desired treatment level. Factors such as flow rate, concentration, and temperature play crucial roles in this process.

Next, various treatment processes such as sedimentation, biological treatment, or advanced oxidation come into consideration, chosen based on the contaminants and desired output quality.

Process engineers pay close attention to efficiency, selecting and optimizing treatment technologies, and designing process sequences that enable water reuse /recycle options. Integrating advanced technologies such as smart sensors for flow monitoring and automation adds another layer of refinement to modern plant designs, promoting overall effectiveness.

What kind of engineers are responsible for designing water treatment plants?

A variety of skilled engineering professionals work together to bring water treatment facilities to life. Environmental engineers often lead the way, their knowledge encompassing water quality regulations, treatment technologies, and sustainable practices. Civil engineers play a vital role in designing the structural foundations and hydraulic systems of the plant, guaranteeing the integrity of the infrastructure.

Chemical engineers leverage their expertise in chemical processes and separations to optimize contaminant removal and ensure safe water quality. In addition, electrical engineers contribute their knowledge to design the electrical systems and control systems for seamless operation. Effective teamwork among these engineers helps deliver a fully functioning retrofitted or new water treatment plant implementation.

What software is used to design wastewater treatment plants?

Sophisticated software tools play an important role in crafting the complex designs of wastewater treatment plants. One software option gaining traction among designers is Transcend, another is Treatment, Optimization & Design (Sasspro®V2), as it has useful tools and spreadsheets. Autodesk Civil 3D empowers engineers to create detailed 3D models for efficient site planning.

Hydraulic modeling software such as EPA SWMM or Bentley SewerGEMS is often employed for simulating and optimizing water flows throughout the treatment process, while AutoCAD Plant 3D provides advanced features for pipe routing, equipment layout, and P&ID creation. The strategic combination of these tools assists engineers in visualizing, analyzing, and fine-tuning their wastewater treatment plant designs for maximum effectiveness.

How much does a wastewater treatment project cost?

The costs for industrial wastewater treatment projects can fluctuate based on many things. This is where Custom design services for industrial wastewater treatment plants are vital because they provide clarity and a tailored approach. However, here’s a general idea based on capacity, and treatment complexity to get a better idea. The cost of retrofitting a plant capable of handling small to medium flows typically ranges between $200,000 to $1,000,000 whereas the cost of retrofitting or implementing a high-capacity treatment facility can soar into the multi-million-dollar range. Factors such as the innovative treatment technology, site conditions and treatment goals weigh significantly in the total costs.