Understanding Industrial Wastewater Treatment Principles

Have you ever pondered the ultimate destination of water utilized in production? Just like a drop of ink spreading through a glass of water, industrial pollutants can spread and wreak havoc on our precious ecosystems. It’s not only the responsibility of industrial leaders; this affects everyone. Industrial wastewater treatment principles, while they may sound technical and distant, are really at the heart of safeguarding our world’s vital lifeblood – clean water. But how do these principles actually work?

This article is your ticket to understanding this complex yet fascinating process. You will discover why heavy metals have no place in our rivers, why source reduction is key, and even get into the nitty-gritty details like pretreatment stages.

Trust me, as you read on, things will become crystal clear. You will see how vital each of us truly is.

Understanding Industrial Wastewater Treatment Principles and Its Impact

Industrial wastewater is a significant contributor to global water pollution. The industrial sector generates an immense amount of wastewater that contains contaminants like heavy metals, organic compounds, and suspended solids.

The Role of Heavy Metals in Industrial Wastewater

Heavy metals like lead, mercury, copper or cadmium amongst others find their way into our water sources through industrial activities. These metals, if not adequately treated or eliminated from wastewater prior to its re-entry into the environment, can be detrimental to both human health and aquatic ecosystems. The EPA’s Aquatic Life Criteria Table gives more details on this issue.

The presence of these suspended solids heavy metals can be harmful if ingested by humans or wildlife. For instance, “Bioaccumulation,” where small amounts build up inside an organism over time leading to toxic levels, is one danger posed by untreated or under treated industrial wastewater.

Organic Compounds in Industrial Wastewater

Besides heavy metals, organic compounds also play a big role in making industrial waste dangerous. These chemicals originate from various industries including pharmaceuticals and pesticides production.

Toxicity level varies based on type; some may cause cancer while others could disrupt hormonal balance in animals and people alike (Pubmed). To make matters worse, these compounds often resist standard treatment methods used at municipal plants, meaning that once introduced into an ecosystem, they tend to stick around.

It’s not just about health risks either. These pollutants can cause catastrophic effects on local ecosystems, leading to the death of aquatic life and rendering water unsafe for human use.

In order to protect our communities and preserve our natural resources, it is crucial that we take action now to better manage industrial wastewater. This includes improving treatment methods and enforcing stricter regulations on industries responsible for creating this waste in the first place.

Principles of Industrial Wastewater Treatment

The treatment of industrial wastewater is no small feat. The three main principles guiding industrial wastewater treatment are source reduction, efficiency optimization, and regulatory compliance.

Source Reduction in Wastewater Treatment

The first principle is all about source reduction. By reducing the generation of wastewater at its origin, we can effectively lessen the load on subsequent stages of treatment.

This step isn’t just practical; it also contributes to a more sustainable approach to water management. It’s like tackling a leaky faucet – why keep mopping up puddles when you could fix the drip?

Compliance with Regulatory Standards

The next cornerstone focuses on compliance with regulatory standards. These guidelines are there for good reason – they protect our environment from harmful substances that might otherwise make their way into our natural water sources.

In this sense, these rules are not just hoops to jump through; they’re guardrails guiding us towards responsible water usage and preservation.

Now let’s bring some numbers into play.

- About 80% of global wastewater goes untreated,

- Nearly 1 billion people lack access to safe drinking water worldwide,

- Every day, the consequences of inadequate wastewater treatment and lack of access to safe drinking water are tragically illustrated by the deaths of hundreds of children under five years old due to diarrheal diseases.

With stats like these, it becomes clear how vital efficient waste processing truly is.

The keyword here? Efficiency. Not only does effective industrial wastewater treatment safeguard public health but also optimizes resources used during production processes.

This brings us back full circle: less waste generated, less treatment needed, fewer pollutants released. A perfect illustration of the saying “less is more”.

So remember: in industrial wastewater treatment, it’s not just about following rules or being efficient – it’s also about looking at the bigger picture and recognizing our role within it.

In Summary:

Industrial wastewater treatment is a crucial, complex process. It’s guided by principles of minimizing pollutants, maximizing efficiency and complying with regulatory standards. The focus on source reduction not only eases subsequent stages but also promotes sustainable water management. Regulatory compliance acts as guardrails towards responsible usage and preservation of water resources.

Stages in Industrial Wastewater Treatment

Treating industrial wastewater is a meticulous process, comprising several stages. It’s like solving a complex puzzle where each piece plays its part.

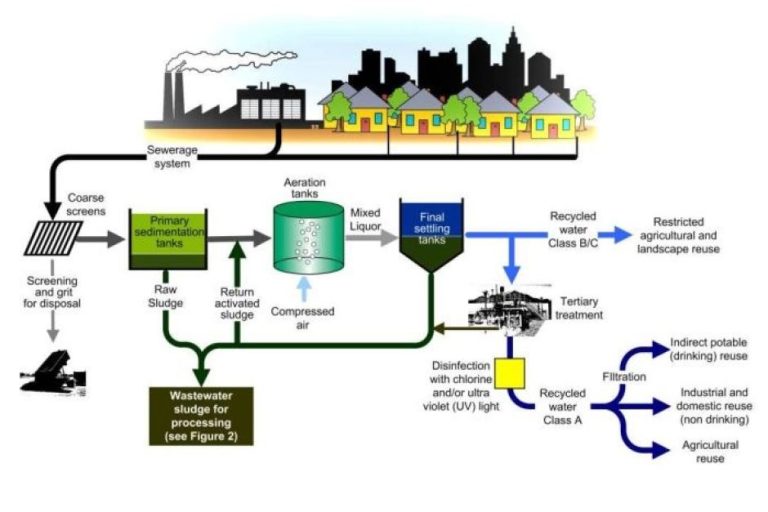

Understanding Pretreatment in Wastewater Treatment

Pretreatment is the first stage of this intriguing journey. Imagine it as sifting through your mail and discarding junk before opening important letters. Here, larger pollutants are removed to protect subsequent treatment units from damage or excessive loading.

The pretreatment phase can also involve adjusting pH levels to neutralize acidic or alkaline wastes because balance is key – not just for our lives but also for effective water treatment.

Primary Treatment: Setting the Stage Right

Moving on, we enter primary treatment which includes clarification. In this process, Zeoturb liquid bio-organic flocculant can be used to assist in the settling of particles – think of it like allowing tea leaves to settle at the bottom of your cup after brewing.

The U.S Environmental Protection Agency (EPA) defines primary treatment as “the removal of substantial amounts of suspended solids and some residual oil.”

Secondary Treatment Processes

We now step into secondary treatment processes that handle what was left behind by previous steps – much like cleaning up after hosting a party. This stage relies heavily on biological processes that use microorganisms to break down organic matter present in wastewater.

In essence, these tiny organisms become heroes who consume harmful substances and convert them into harmless end products.

This ‘biological banquet’ results in cleaner water ready for further refinement.

Tertiary Treatment: The Finishing Touches

Following secondary treatment, we have tertiary treatment. This stage is like the final touch-up on a painting, making sure every detail is perfect.

In this phase, additional contaminants are removed through methods such as filtration and disinfection. It’s all about fine-tuning to ensure water quality meets specific standards before it can be safely discharged or reused.

The EPA says, “Tertiary treatment could include physical-chemical separation methods like filtration using Natzeo media or Activated carbon media.”

The Role of Sludge Treatment in Wastewater Management

Sludge treatment plays a crucial part in wastewater management. It’s the last line of defense before water gets reintroduced into our environment.

A Closer Look at Sludge and Its Treatment

What exactly is sludge? Think about it as the villainous blob from a sci-fi movie, but in reality, it’s less threatening – just suspended solids left behind after primary and secondary wastewater treatments. These solids need to be dealt with because they can carry heavy metals or harmful organic compounds that are detrimental to ecosystems if not properly managed.

Treating sludge isn’t simply tossing it out. In fact, getting rid of this byproduct involves several steps: thickening (concentrating), digestion (breaking down organics), dewatering (removing more water), and disposal or reuse (according to EPA guidelines). The goal here is to minimize environmental impact while maximizing resource recovery opportunities such as energy generation or soil amendment production.

Why Should We Care About Sludge?

We should care about sludge for one simple reason: our planet’s health depends on how we manage waste. Improperly treated sludge poses serious threats – think toxic algal blooms choking aquatic life due to nutrient overload. However, when correctly processed, this so-called waste becomes an asset.

- Sustainable Energy: Methane produced during anaerobic digestion can power facilities making these operations self-sustaining.

- Nutrient Recovery: Treated biosolids make excellent fertilizers, returning essential nutrients back to the soil.

- Land Reclamation: With careful monitoring, biosolids can help restore depleted mine sites or eroded lands. (EPA)

The Bigger Picture: Genesis Water Technologies and Industrial Water Management

We at Genesis Water Technologies know our stuff when it comes to managing industrial process water and wastewater. Our goal? To make sure we are not just treating water but doing so in a way that values sustainability and resource recovery.

We’ve got you covered in your industrial wastewater journey.

Conclusion

Are you ready to take action and become a guardian of clean water and a champion of sustainable industrial practices? As we conclude our journey into the world of industrial wastewater treatment, it’s evident that the impact of this process goes far beyond factories and treatment plants.

The health of our communities depends on responsible industrial water management, and it’s a shared responsibility. As you reflect on what you’ve learned today, consider how you can contribute to a more sustainable, clean water future. Whether you work in an industrial company, regulatory agencies, or consulting engineering firm, your role in this journey is crucial.

As we navigate these challenges, Genesis Water Technologies stands ready to assist and guide you in managing industrial process water and wastewater sustainably using advanced treatment technologies. Let’s work together to ensure that our impact on the environment is a positive one, making the most of available resources and preserving the delicate balance of our ecosystems.

Are you ready to embrace a future where sustainable practices lead the way? Contact us today at +1 877 267 3699 or email us at customersupport@genesiswatertech.com. Together, we can make a lasting impact on industrial water management. Join us in championing a cleaner, more sustainable world.