How To Scope Water Reuse Projects with Innovative Water Technologies

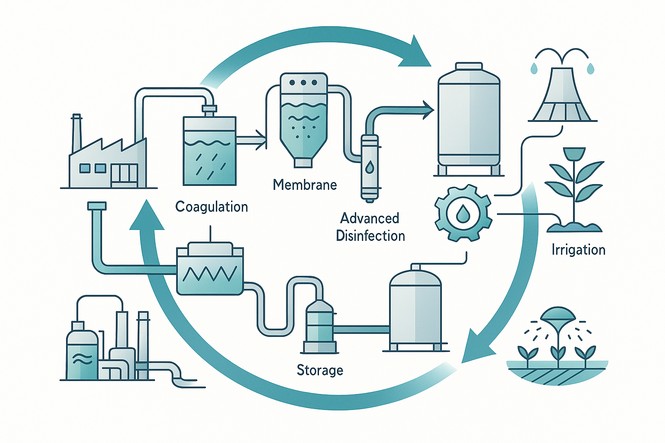

Water scarcity pressures and stricter discharge regulations are driving industrial facilities and municipal operators to implement comprehensive water reuse strategies. However, successful water reuse projects require methodical scoping that matches treatment technologies to specific water quality parameters and operational constraints. This systematic approach prevents costly oversizing, ensures regulatory compliance, and maximizes return on investment.

Understanding Your Water Reuse Baseline

The foundation of any water reuse project begins with comprehensive characterization of your existing water streams. Plant managers often underestimate the variability in their process water, leading to treatment system failures during peak contamination periods.

Start by collecting samples from all potential source streams across different operating conditions. Industrial facilities should sample during maximum production loads, cleaning cycles, and seasonal variations. Municipal operators need data spanning wet weather events, peak demand periods, and varying influent characteristics.

Critical parameters to analyze include total suspended solids (TSS), chemical oxygen demand (COD), total dissolved solids (TDS), heavy metals, pH fluctuations, and specific contaminants unique to your process. For pharmaceutical manufacturing, this might include active pharmaceutical ingredients (APIs). Food processing facilities must account for fats, oils, and grease (FOG) concentrations that vary dramatically between product runs.

Document your current water consumption patterns and discharge volumes. Many facilities discover significant water loss through inefficient cooling tower blowdown, boiler blowdown, or process rinse cycles that represent immediate reuse opportunities.

Defining Water Quality Targets for Reuse Applications

Water reuse success hinges on matching treated water quality to end-use requirements. Different applications demand vastly different quality standards, and over-treatment wastes capital and operating resources.

Cooling tower makeup water typically requires TSS below 25 mg/L and calcium hardness under 200 mg/L as CaCO3 to prevent scaling. However, some newer cooling tower designs can accept higher TDS levels with appropriate corrosion inhibitors, potentially eliminating expensive reverse osmosis steps.

Process water requirements vary significantly by industry. Electronics manufacturing demands ultra-pure water with resistivity above 10 MΩ-cm, while concrete production can utilize water with TDS levels exceeding 1,000 mg/L. Understanding these specific requirements prevents unnecessary treatment stages.

Boiler feedwater quality depends on operating pressure. Low-pressure boilers (under 300 psig) may accept TDS up to 3,000 mg/L, while high-pressure systems require near-distilled water quality. This distinction significantly impacts treatment technology selection.

For irrigation applications, consider sodium adsorption ratio (SAR), chloride content, and boron concentrations that affect plant health. Municipal reuse projects must meet Title 22 standards in California or equivalent regulations in other jurisdictions.

Technology Selection Framework

Selecting appropriate treatment technologies requires matching contaminant removal capabilities to water quality gaps between source and target specifications.

Electrocoagulation for Complex Industrial Streams

Electrocoagulation excels at removing suspended solids, emulsified oils, and heavy metals through in-situ coagulant generation. Unlike chemical coagulation, electrocoagulation produces minimal sludge volume and eliminates ongoing chemical costs.

Size electrocoagulation systems based on hydraulic residence time requirements, typically 15-30 minutes for industrial wastewater. Power consumption ranges from 2-8 kWh per cubic meter treated, depending on conductivity and contaminant loading. Higher conductivity reduces power requirements but may necessitate downstream desalination.

Electrocoagulation works particularly well for metal finishing wastewater, food processing streams with high FOG content, and pharmaceutical manufacturing where complex organic molecules require destruction rather than simple separation.

Natzeo for Dual-Function Filtration and Ion Exchange

Natural zeolite media like Natzeo provide both physical filtration and selective ion exchange capabilities in a single treatment step. This media effectively removes suspended solids down to approximately 5 microns while simultaneously providing cost-effective removal of ammonia, heavy metals, and specific dissolved ions. Natzeo offers higher selectivity than traditional ion exchange resins for certain applications.

Size Natzeo backwash filtration systems based on empty bed contact time (EBCT) of 5-15 minutes for ion exchange applications, or surface loading rates of 1o-12 gpm/ft² for filtration applications. When used for combined filtration and ion exchange, design for the more restrictive parameter. Breakthrough capacity varies with competing ions and suspended solids loading, so pilot testing with actual wastewater is essential for accurate sizing.

Zeoturb Bio-Organic Flocculant for Enhanced Coagulation

Zeoturb is a liquid bio-organic flocculant that provides superior performance compared to traditional aluminum or iron-based coagulants. This bio-based solution effectively removes suspended solids, turbidity, and colloidal particles while producing less sludge volume.

Dose Zeoturb at rates typically ranging from 30-100 mg/L, depending on raw water quality and target clarification efficiency. The bio-organic nature allows for wider pH operating ranges and improved floc formation in challenging water matrices. This technology works particularly well for pre-treatment ahead of membrane systems or as primary clarification for high-turbidity industrial streams.

Activated Carbon Systems for Organic Contaminant Control

Granular activated carbon (GAC) removes dissolved organics, chlorinated compounds, and trace pharmaceuticals that other technologies cannot address effectively.

Size GAC contactors using the empty bed contact time approach, with EBCT ranging from 10-30 minutes based on target contaminants. Shorter contact times work for easily adsorbed compounds like chlorinated solvents, while longer times are needed for complex organics or low breakthrough concentrations.

Consider carbon regeneration economics early in the design process. On-site thermal regeneration becomes cost-effective at carbon replacement rates exceeding 1,000 pounds per month. Smaller facilities typically use virgin carbon with off-site regeneration or disposal.

GCAT and Genclean for Advanced Oxidation

Advanced oxidation processes like Genclean and GCAT (Catalytic Activation Treatment) assist in remediating recalcitrant organics that resist biological treatment. These systems generate reactive oxygen and hydroxyl radical compounds that break down complex molecules into biodegradable intermediates.

Size advanced oxidation systems based on required log reduction of target contaminants. Typical residence times range from 30-120 minutes with Genclean doses of 1-3.0 mg per mg COD. Higher doses may be required for compounds with low reactivity to reactive oxygen or hydroxyl radical compounds.

Tertiary Reverse Osmosis for Polishing

Tertiary reverse osmosis provides final polishing for high-purity applications or zero liquid discharge (ZLD) systems. Modern RO membranes achieve 99%+ rejection of dissolved salts and most organic molecules.

Size RO systems based on required recovery rate, typically 75-85% for most industrial applications. Higher recovery rates increase concentrate disposal costs and may require additional pretreatment. Consider split-pass configurations for applications requiring both high recovery and stringent permeate quality.

Antiscalant selection significantly impacts system performance. Broad spectrum antiscalants may be inadequate for challenging feed waters, while specialized products such as Vitec 4000 can enable higher recovery rates and longer cleaning intervals.

Sizing Methodologies and Design Considerations

Accurate sizing prevents both capital waste and operational failures. Start with average flow rates but design for peak conditions, including upset conditions and cleaning cycles using an equalization tank.

Apply appropriate safety factors based on technology maturity and process criticality. Proven technologies like activated sludge may use 1.25-1.5 safety factors, while newer technologies might require 2.0 or higher until performance is verified.

Consider seasonal variations in both flow and quality. Many industrial facilities experience 50-100% flow variations between peak and minimum production periods. Municipal systems face similar variations with wet weather events and tourism cycles.

Plan for redundancy in critical treatment steps. Biological systems should have backup aeration capacity. Chemical feed systems need redundant pumps and storage. Membrane systems require spare capacity for cleaning rotations.

Pilot Testing and Validation Requirements

Pilot testing validates treatment performance under actual operating conditions and refines design parameters. Skip pilot testing only for well-established technology combinations with extensive performance data.

Design pilot systems to test limiting conditions, not just average performance. Run pilots during maximum contamination periods and stress-test with expected upset conditions.

Duration matters more than scale for biological systems. Run activated sludge pilots for minimum 60 days to establish stable biomass. Membrane bioreactor pilots need 90+ days to develop characteristic fouling patterns.

For membrane systems, pilot testing determines accurate flux rates, cleaning frequencies, and chemical compatibility. Laboratory-scale tests cannot fully predict actual fouling behavior in complex industrial wastewater.

Economic Optimization Strategies

Life-cycle cost analysis should include all capital, operating, and risk mitigation costs over the system’s expected lifetime.

Energy consumption often dominates operating costs for advanced treatment systems. Evaluate power costs at different tariff rates and consider time-of-use pricing for energy-intensive processes like electrocoagulation or UV disinfection.

Chemical costs vary significantly with procurement strategy. Long-term contracts provide cost stability but reduce flexibility. Bulk storage reduces per-unit costs but increases working capital requirements.

Maintenance costs correlate strongly with system complexity and automation level. Highly automated systems reduce labor costs but increase spare parts inventory and specialized maintenance requirements.

Consider regulatory risk in economic analysis. Stricter discharge limits or water scarcity may dramatically increase the value of reuse capacity, justifying higher initial investment in robust treatment systems.

Implementation Timeline and Risk Management

Successful water reuse projects require careful sequencing of design, permitting, construction, and commissioning activities.

Begin regulatory discussions early in the scoping process. Permit timelines for water reuse projects often exceed 12-18 months, particularly for direct potable reuse or industrial discharge elimination.

Plan for extended startup periods with new technology combinations. Complex treatment trains may require 3-6 months of optimization before achieving design performance.

Develop contingency plans for treatment system failures during critical production periods. This might include temporary chemical treatment, trucked water supply, or reduced production capacity.

Moving Forward with Your Water Reuse Project

Proper scoping of water reuse projects with innovative technologies requires balancing technical performance, economic optimization, and risk management. Success depends on thorough characterization of existing water streams, realistic assessment of treatment requirements, and careful selection of proven technologies appropriate for specific applications.

The complexity of modern industrial and municipal water systems demands expertise in both established and emerging treatment technologies. Working with experienced water treatment professionals ensures that technology selection, sizing, and integration decisions are based on sound engineering principles and real-world performance data.

Ready to optimize your water reuse strategy? Contact the water treatment specialists at Genesis Water Technologies by email at customersupport@genesiswatertech.com to schedule a comprehensive process review. Our team will evaluate your specific water streams, regulatory requirements, and operational constraints to develop a tailored treatment solution that maximizes water recovery while minimizing life-cycle costs.