How To Choose the Appropriate AOP Process for Wastewater Treatment

Oxidation is the driving force for many water and wastewater treatment solutions. One solution, in particular, is designed around maximizing the oxidation potential of the system. This particular process is the AOP process.

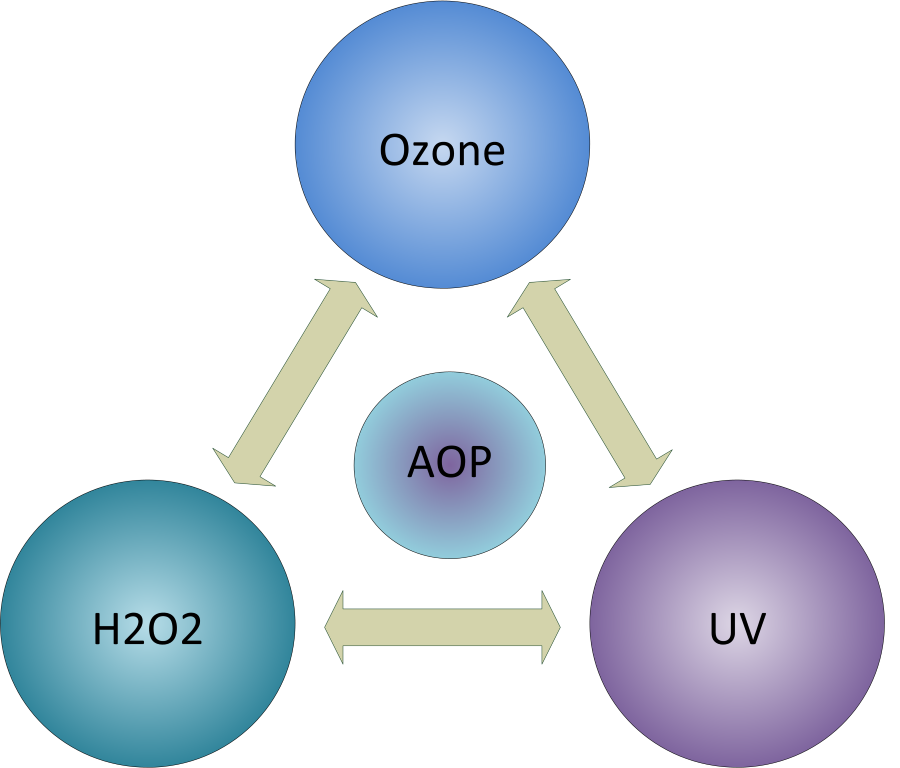

The advanced oxidation (AOP) process, dubbed so by William Glaze and company in 1987, typically refer to processes that produce hydroxyl radicals (⦁OH). These radicals are the primary oxidants that carry out this process, breaking down compounds into intermediates and then mineralizing those intermediates into simple compounds like water, carbon dioxide, and salts. There are several different ways these radicals can be produced. In general, these AOP molecules are formed as particular compounds degrade, compounds such as ozone (O3) and hydrogen peroxide (H2O2) in particular. Other components, like ultraviolet light (UV), are used as catalysts in the reaction to encourage the compounds to break down accordingly.

However, as with many water/wastewater treatment solutions, there are upsides and downsides to the different options. Therefore, it is important to carefully choose an AOP process that will work best with your particular application. How do you make such a choice? By knowing some of the basic information of each AOP process.

First, it would help to know a bit about some of the options available in each AOP process and how these options work.

Types of AOP:

Ozone

Ozone interacts with hydrogen-containing compounds and decomposes in a series of steps to reduce to ⦁OH radicals in an alkaline solution. It can be used on its own as an AOP, typically at higher pH levels due to the abundance of hydroxide ions present. O3 itself is also a powerful oxidant and acts as a secondary oxidizer in the overall process, though the reactions are much slower. If used, O3 must be generated on site and used quickly, as it has a very short half-life. In addition, if bromide is one of the contaminants in the wastewater, there is potential for the formation of bromates molecules, which are highly toxic.

Hydrogen Peroxide

Hydrogen peroxide cannot be used as a standalone oxidation treatment like ozone. It is not as strong of a secondary oxidizer as O3 but it can react with hydrogen and oxygen-containing compounds in a less complex process than ozone. It does not need to be produced on site, but it does need to be kept in careful storage as it is unstable. H2O2 also needs to be monitored for residuals leftover after treatment. The compound can be toxic to humans, so it may need to be treated for.

Ultraviolet Light

Ultraviolet light is used quite commonly as a disinfectant, for its ability to kill or prohibit the reproduction of a number of pathogens. As it is merely a wavelength of light, UV is not itself an oxidant, but it transfers massless photons to chemical compounds; breaking their bonds quickly and easily. However, being light driven, some contaminants including suspended solids can reduce the efficiency of UV interaction by blocking it from the target compounds.

Combinations

Most often, the treatments above are used in some combination with one another: O3/UV, O3/H2O2, H2O2/UV, O3/H2O2/UV. These combinations use the strengths of these individual processes to improve the efficiency of the overall AOP process. However, each combination does have some of drawbacks, therefore, the optimized process is chosen based on application.

Next, it is pertinent to mention what considerations must be taken into account when choosing the correct AOP process for a particular application.

Things to consider:

Water composition

Perhaps most obviously, the composition of the influent water should be carefully considered. AOP is a heavily involved chemical process, and therefore, decisions on what process to use are dependent on what particular pollutants are within the water to be treated.

Treatment goals

Environmental regulations or reuse considerations determine how much the water/wastewater needs to be treated. More lax standards may only need a simple process, while stricter standards require something a little stronger.

UV dose

As with the typical UV disinfection process, an appropriate amount of UV exposure is required to achieve the desired results without drawing unnecessary levels of energy making this process uneconomical.

Chemical dose

In order to achieve an acceptable concentration of ⦁OH radicals, sufficient doses of O3 and/or H2O2 need to be added in order to do that. Again, this is a chemistry intensive process and chemistry demands proper dosing or else you will not get the desired results.

Energy consumption

The AOP process can be a fairly energy intensive system in some cases, certain system configurations or applications requiring more than others.

Cost

AOP process systems tend towards higher costs in general, but certain systems do cost more than others. The most significant costs deal with operational aspects to keep up with the need for input chemicals and energy based on contaminant levels.

Lastly, you may require the assistance of a process engineering firm that specializes in water treatment. In many cases, choosing the proper system can fall to past experience. It can be difficult to tell how a system will work just based on theory. It can take hours of research and testing, and an engineer may have dealt with all of that in a previous, yet similar application.

So, carefully consider your options and how they may apply to you. After doing this, find a firm who has done work on a similar project before and they can potentially advise you on how it might work out.

Do you need some guidance while choosing an AOP process for your wastewater treatment application? Contact Genesis Water Technologies at 1-877-267-3699, via our local offices worldwide, or by email at customersupport@genesiswatertech.com for a free initial consultation.