Decoding Aerobic Treatment: Organic Matter to Clean Water

How does aerobic treatment convert organic matter in industrial wastewater applications? This question may seem daunting to some.

Truth is, when it comes to understanding the complex processes of wastewater treatment, many are left scratching their heads…

This process involves biology and chemistry, two subjects that can make even the most dedicated environmental enthusiasts break out in a cold sweat. However, this is what separates those who simply want clean water from the wastewater management experts.

If you are not familiar with how aerobic treatment works to transform harmful pollutants into harmless byproducts, you might feel like you will never grasp these critical concepts.

Cleaning up our precious water resources is not easy work, folks.

Take for instance one factory owner who confessed his confusion over why he needed an intricate system just to treat his companies wastewater output… That was

Table of Contents:

- The Necessity of Wastewater Treatment in Industrial Settings

- Eutrophication – A Consequence of Inadequate Treatment

- Understanding Aerobic Wastewater Treatment

- Activated Sludge Systems and Aerated Stabilization Basins

- Role of Oxygen in Aerobic Treatment

- Anaerobic Wastewater Treatment – An Overview

- Comparing Aerobic vs Anaerobic Processes

- Advanced Aerobic Treatment Methods for Industrial Wastewater

- Achieving High-Quality Reclaimed Water

- Understanding Advanced Techniques: The Bigger Picture

- Regulatory Standards for Wastewater Treatment

- The Importance of Adhering to Regulatory Standards

- Choosing Between Aerobic & Anaerobic Systems – Factors to Consider

- The Nature of Organic Loadings

- Bioenergy – Cogeneration Potential Advantage

- Oxygen Uptake Rate vs Energy Requirements

- Choosing Between Aerobic & Anaerobic Systems – Factors to Consider

- Organic Loadings & Energy Requirements

- Regulatory Standards & Byproduct Utilization

- FAQs in Relation to How Does Aerobic Treatment Convert Organic Matter in industrial Wastewater?

- What is aerobic treatment of industrial wastewater?

- What is aerobic treatment of organic wastes?

- Which step of wastewater treatment process utilizes aerobic microorganisms to metabolize the organic matter?

- What is the role of anaerobic treatment in industrial waste treatment?

- Exploring the fascinating world of biological water treatment

The Necessity of Wastewater Treatment in Industrial Settings

Consider this: industrial wastewater treatment is not just about regulatory compliance. Maintaining public health and safeguarding the environment are essential aspects of treating industrial wastewater. The potential harm that untreated or poorly treated industrial effluent can inflict on human health and ecological systems is significant.

This wastewater effluent has the power to cause severe environmental damage if not properly managed through effective wastewater treatment processes like aerobic treatment or anaerobic systems.

Eutrophication – A Consequence of Inadequate Treatment

Eutrophication is one such consequence we need to be aware of when discussing inadequate wastewater management. This phenomenon occurs when excess nutrients from untreated industrial effluents enter bodies of water, causing algal blooms which subsequently deplete dissolved oxygen levels, adversely affecting aquatic life.

Understanding Aerobic Wastewater Treatment

In the realm of industrial wastewater treatment, aerobic methods have carved out a notable role. This process leverages oxygen to degrade organic matter and pollutants in the waste stream. This approach is instrumental for achieving optimal degradation while staying within environmental regulations.

Bioreactor Systems Activated Sludge Systems & Aerated Stabilization Basins

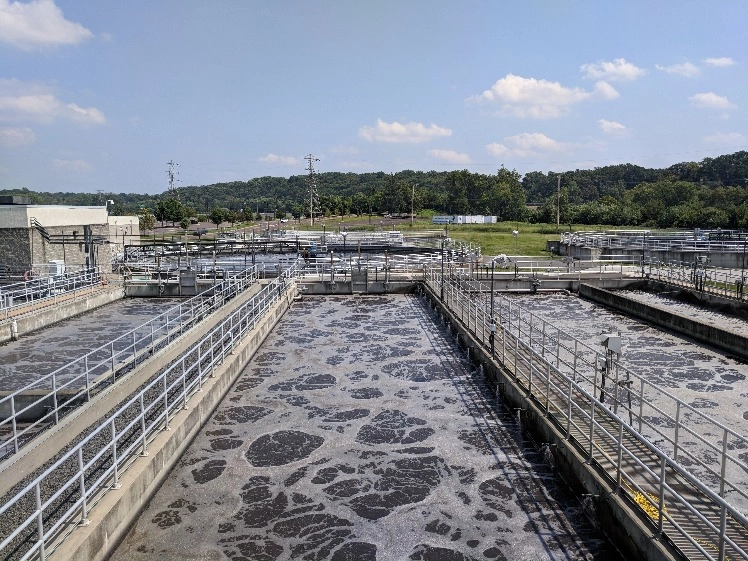

Aerobic treatment utilizes three primary systems: bioreactor systems such as MBR and MBBR, activated sludge systems and aerated stabilization basins (ASBs). In these systems, bacteria utilize oxygen to break down organic material inside aeration tanks before moving into clarification or membrane separation tanks where biomass is separated and removed.

The ASB method takes place over extended periods in large open-air ponds with similar processes occurring at slower rates. Industries such as pulp & paper frequently employ these techniques due to their efficacy in reducing high levels of biochemical oxygen demand (BOD) along with suspended solids.

Role of Oxygen in Aerobic Treatment

Oxygen plays a pivotal part within this context; it’s not just about the presence but also quantity. Adequate dissolved oxygen levels are crucial in wastewater treatment. These levels enable aerobic bacteria to decompose complex organics into simpler substances like carbon dioxide and water efficiently and effectively.

This need for sufficient quantities of oxygen is encapsulated by BOD – Biochemical Oxygen Demand – which quantifies how much dissolved oxygen would be consumed under ideal conditions by microbes. This is measured by the break down of organics present per liter of sample over a five day period at 20°C. Therefore, maintaining appropriate concentrations becomes paramount when seeking efficient pollutant removal through aerobic treatment technologies.

Anaerobic Wastewater Treatment – An Overview

While aerobic treatment requires oxygen to function, anaerobic wastewater treatment operates in its absence. This approach is particularly effective for industrial wastewater that carries a high concentration of organic matter.

The benefits of this process are numerous and significant. One such advantage is the production of biogas – a renewable energy source with potential use within the facility itself. In addition, compared to their aerobic counterparts, anaerobic systems require less energy input and yield reduced sludge output.

Comparing Aerobic vs Anaerobic Processes

A decision between implementing an aerobic or an anaerobic system depends on several factors including characteristics inherent to the specific type of wastewater being treated as well as desired outcomes from the treatment process itself.

A typical activated sludge wastewater system might be more suitable due to its ability to provide sufficient oxygen supply required by bacteria for degrading organic material efficiently.

On the other hand, an anaerobic system offers advantages such as biogas production and reduced energy and sludge output. The choice ultimately lies in balancing these variables while ensuring compliance with regulatory standards established globally for safe discharge into the surrounding environment.

Advanced Aerobic Treatment Methods for Industrial Wastewater

In the sphere of industrial wastewater treatment, advanced aerobic methods have emerged as game-changers. They’re not just about breaking down organic material – these techniques are also engineered to generally produce adequate quality effluent that’s ready for reuse or safe disposal.

Achieving High-Quality Reclaimed Water

The secret weapon in some of these innovative treatments? Archaea, a type of microorganism known for its resilience under extreme conditions and knack for pollutant degradation.

This isn’t where innovation ends though. Vacuum microbubble diffused aeration is another method which amplifies the oxygen uptake rate by creating minuscule microbubbles providing more surface area for gas exchange. These systems are utilized in both aeration tanks as well as ponds. Similarly, GWT AB jet aeration uses high-velocity jets enhancing mixing and promoting better contact between bacteria and organic matter thereby boosting degradation processes. These systems are typically utilized in deeper aeration basins.

Understanding Advanced Techniques: The Bigger Picture

It is essential to grasp the advantages each technique offers in order to fully comprehend how far we have advanced our wastewater management strategies; this involves understanding high-level concepts.

Regulatory Standards for Wastewater Treatment

Greywater standards are a key component of wastewater treatment regulations worldwide. These guidelines aim to safeguard public health and the environment by setting limits on industrial discharges.

The EPA enforces strict regulations under the Clean Water Act in the US. The act stipulates that industries must treat their wastewater before it is discharged into water bodies or municipal sewer systems. Furthermore, EPA has industry-specific effluent limitations in place.

Moving across to Europe, similar directives from the European Union (EU) regulate this sector. A notable example would be the EU’s Urban Waste Water Treatment Directive which mandates member states to establish proper collection and treatment systems for urban wastewater ensuring treated water meets specific quality parameters prior releasing into sensitive water areas.

The Importance of Adhering to Regulatory Standards

Falling short on these regulatory standards can lead down a slippery slope towards hefty fines and potential operational shutdowns – an outcome no business desires. Henceforth, companies invest significantly in effective aerobic & anaerobic processes as part of their industrial wastewater treatment strategies.

Beyond just avoiding legal implications though – compliance with these regulations also plays a significant role in shaping corporate social responsibility efforts while managing brand reputation effectively. Companies demonstrating commitment towards sustainable practices often find themselves enjoying improved stakeholder relationships along with increased customer loyalty. These benefits are not easily quantifiable but invaluable in all cases nonetheless.

Choosing Between Aerobic & Anaerobic Systems – Factors to Consider

A decision between aerobic and anaerobic wastewater treatment systems is far from simple. Each system has its own merits, depending on the specific requirements of your industrial process.

Here are some key factors that can guide you in making an informed choice:

The Nature of Organic Loadings

In what form does organic matter exist in your wastewater? Is it easily degradable or complex?

If your waste stream contains readily biodegradable organic material, then aerated wastewater systems, which use oxygen-loving bacteria for degradation, might be a good fit. However, if the waste consists mainly of complex compounds like fats and proteins, anaerobic microorganisms may do a better job breaking them down into simpler substances.

Bioenergy – Cogeneration Potential Advantage

Also known as combined heat and power (CHP), cogeneration refers to the simultaneous production of electricity and useful heat from one energy source, such as biogas.

Anaerobic processes produce methane-rich biogas during decomposition, a valuable byproduct that could be used for cogeneration purposes.

So when considering energy efficiency at large-scale operations with high concentrations of organics, anaerobic processes take center stage.

Oxygen Uptake Rate vs Energy Requirements

A key differentiator between these two types lies within their oxygen needs: while aerobic bacteria utilize oxygen directly from the air “an abundant resource indeed” anaerobic bacteria do not require any external air supply. Hence saving considerable costs related to aeration equipment operation and maintenance over time.

In conclusion, the choice is not always black-and-white but requires careful consideration based on several variables, including the type and amounts involved, along with financial and environmental constraints, among others consideration points.

Choosing Between Aerobic & Anaerobic Systems – Factors to Consider

The decision between aerobic treatment and anaerobic wastewater treatment methods is a pivotal one for environmental consultants, plant managers, or anyone involved in industrial wastewater management. There are numerous factors at play here – the type of organic loadings present in your waste stream, energy requirements of each system, potential byproducts like biogas from cogeneration, and more.

Anaerobic systems may seem attractive due to their ability to produce valuable biogas during the degradation process. This can be especially beneficial for industries with high-energy demands as it could lead to significant cost savings despite higher initial setup costs.

Organic Loading & Energy Requirements

Your choice will largely depend on what exactly you’re dealing with when it comes down to your specific wastewater composition. If there is a high quantity of organic matter that needs tackling, then an anaerobic approach might serve best since these processes have proven effective at converting such wastes into useful byproducts like bio gas.

A different story unfolds if we are talking about lower levels of organics but pathogens needing oxygen-rich environments for proper disposal. This tends to indicate loud and clear for an aerobic solution which also tends not to require heating elements typically associated with anaerobic processes, thereby reducing overall energy consumption.

Regulatory Standards & Byproduct Utilization

You will need compliance too. Local regulations dictate effluent quality standards which can significantly influence whether you lean towards either method over another. This will depend upon how strict they get around biochemical oxygen demand (BOD) limits and other parameters. In many cases forcing us onto advanced paths using pre and post treatment solutions like clarification using Zeoturb liquid bio-organic flocculant, electrocoagulation or AOP disinfection where possible. Let’s face it: nobody wants trouble.

FAQs in Relation to How Does Aerobic Treatment Convert Organic Matter in industrial Wastewater?

What is aerobic treatment of industrial wastewater?

Aerobic treatment uses oxygen and bacteria to break down organic matter in industrial wastewater, transforming it into clean water ready for tertiary treatment based on sustainable discharge or reuse regulations.

What is aerobic treatment of organic wastes?

Aerobic treatment involves the use of microorganisms that require oxygen to decompose organic waste materials effectively.

Which step of the wastewater treatment process utilizes aerobic microorganisms to metabolize the organic matter?

The secondary stage or biological treatment phase employs aerobic microorganisms for metabolizing the biodegradable dissolved and suspended organic matter in these wastewater streams.

What is the role of anaerobic treatment in industrial waste treatment?

Anaerobic processes treat high-concentration waste streams by breaking down pollutants without using oxygen, often producing biogas as a beneficial byproduct of this treatment process.

Exploring the Fascinating World of Aerobic Wastewater Treatment

Understanding the process of wastewater treatment is no small feat.

The intricacies of how aerobic treatment converts organic matter in industrial wastewater are fascinating, to say the least.

We’ve seen that this involves using oxygen and bacteria to break down biodegradable pollutants into harmless byproducts.

It is a complex dance between biology and chemistry, with MBR, MBBR, activated sludge systems and aerated stabilization basins taking center stage.

Anaerobic processes also play their part when conditions demand it, adding another layer to this intricate ballet.

Moving beyond traditional methods, advanced techniques like GWT Biostik aerobic biological treatment or Vacuum microbubble diffused aeration have been making waves for their effectiveness in producing high-quality reclaimed water from waste streams, ponds and lagoons.

Regulatory standards ensure safety while routine maintenance guarantees system performance – both essential elements for sustainable water management practices.

Aerobic vs anaerobic? The choice depends on various factors such as organic loading or energy requirements – each has its place depending on your specific needs.

Genesis Water Technologies is committed to providing sustainable water treatment technologies and services, and can help you and your consulting engineers navigate these complexities within existing or new treatment processes for your organizations.

Want to discover more about the issues that a biological treatment process can help your organization solve? Contact the water & wastewater treatment experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or reach out to us via email at customersupport@genesiswatertech.com to discuss your specific application. We look forward to hearing from you.