4 Produced Water Treatment Technologies to Meet Regulations

In the U.S. alone, oil and gas production is skyrocketing. In the first two months of 2023, oil and gas production increased to 5,985 billion cubic feet, a record number that surpasses the 5,600 billion cubic feet the industry saw in the same period in 2022. The U.S. Energy Information Administration predicts that crude oil production will continue to increase and hit new records in 2023 and 2024. However, with this increase comes an increase in produced water, which is already available in high amounts, making produced water treatment technologies even more critical.

The Impact of Produced Water

Produced water is the largest waste stream linked to oil and gas production, containing total suspended solids, non-soluble oil and organics, dissolved solids, sulfur-reducing bacteria, and other chemicals. The Environmental Protection Agency (EPA) estimates that 20 to 25 billion barrels of produced water are generated in the U.S. annually. When looking at global produced water production, that number jumps to 250 million barrels per day compared to about 80 million barrels of oil per day.

Given the toxicity and volume of produced water, operators are facing increasingly strict regulatory standards. In some instances, these regulations are easier to meet. For example, when operators plan to reuse their produced water for a particular process, the water quality regulations are less stringent than if operators were discharging the produced water into a well or a surface water source. That being said, the location of operators’ discharged produced water determines the severity of the regulations they must follow. Consequently, some operators are choosing to reuse their produced water since the associated standards are easier to comply with—plus, the method is more environmentally friendly.

In water-stressed places like West Texas, California, and New Mexico, water reuse by oil and gas companies is particularly critical. With droughts increasing in those areas, operators cannot continue to rely solely on freshwater sources to complete certain processes. In that respect, water reuse has multiple benefits: operators can decrease pressure on the environment and find less stringent water quality standards.

However, operators must remember that water reuse isn’t a way to escape excellent produced water treatment. While the regulatory guidelines are less strict for water reuse than for discharges into the environment, they are still rigid. So regardless of where operators put their produced water, they need to use advanced technologies to stay compliant.

Optimized Produced Water Treatment Technologies

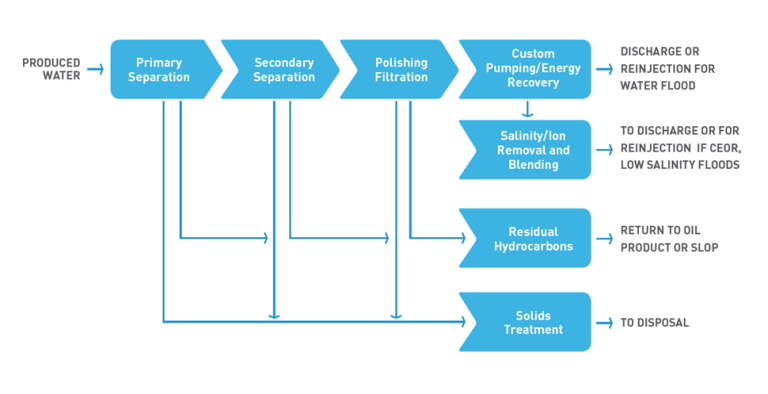

Most oil and gas operators face three challenges when treating produced water: total suspended solids, oil and grease content, and sulfur-reducing bacteria. These are the most common contaminants that operators have to address, but sometimes they must consider removing other things like salt. Ultimately, the produced water treatment technologies operators use will depend on the contaminants that regulatory standards tell them to address.

Some technologies handle one particular contaminant, while others tackle a different one. That means operators may need a treatment process encompassing different technologies to achieve a specific water quality result.

With every produced water treatment technology, there are benefits and costs that operators will have to evaluate to determine the best solution to use. However, to make the evaluation process easier, below are four optimized produced water treatment technologies operators should consider. Each one has plenty of pros, helps meet rigid regulations, and is environmentally friendly.

1. Self Cleaning Centrifugal Filtration

Centrifugal filtration is a mechanical method that uses a centrifuge to remove suspended solids from a source water stream. With a self-cleaning configuration, the technology has specific capabilities to filter high levels of total suspended solids (TSS) with particles sizes up to 2000 micron. In fact, it can filter up to 10,000mg/l TSS in a wastewater stream even if trace amounts of oil and grease are present, so it’s an excellent solution for the environment.

2. Zeoturb

An environmentally-safe technology, Zeoturb liquid bio-organic flocculant is used in the clarification process. It reduces and removes organic and inorganic particles like sediments, silt, dyes, algae, and trace amounts of certain heavy metals. It also assists in trace oil and grease and certain dissolved contaminant removal.

3. Specialized Electrocoagulation

This produced water treatment technology helps cut waste and costs. With electrocoagulation, operators can remove large quantities of contaminants in a single operation, so this solution is both environmentally friendly and cost-effective. Operators can typically utilize this technology with post clarification along with Zeoturb introduction. Determining whether to use the technologies together will depend on the requirements operators must meet.

4. Genclean-Ind

Genclean-Ind is a non-toxic, specialized NSF-certified advanced oxidation water treatment liquid solution. It’s designed for the oxidation, disinfection, and reduction of organic contaminants, microbiological pathogens, and trace metals in produced water and industrial water. The technology is used during post-filtration and doesn’t come with the risks linked to toxic byproducts typically associated with ozone and chlorine treatment systems, so it’s another environmentally-friendly solution developed for industrial applications.

Choose Advanced Treatment Technologies

Oil and gas production isn’t slowing down. however, if operators want to maintain and pick up the pace without facing scrutiny from regulatory or environmental bodies, they need to treat the growing amounts of produced water they will generate from increasing oil production.

The top four technologies are important for operators to consider, regardless of whether they plan to reuse their produced water or discharge it in a well or a surface water source. If operators need help locating the top four produced water treatment solutions, Genesis Water Technologies has them and is ready to to work with your organization to meet rigid regulations and your specific needs.

Use these innovative, advanced technologies to treat produced water by contacting Genesis Water Technologies and our team of water & wastewater treatment experts at +1 877 267 3699 or via email at customersupport@genesiswatertech.com.