Coagulation Water Treatment vs. Electrocoagulation Treatment

There are many ways to treat water, and one of the most common tactics is coagulation. This method provides clean, safe water and is typically used alongside other standard processes like sedimentation, disinfection, and filtration.

All of these methods assist in removing contaminants from water. However, while coagulation water treatment is a good conventional option, a better solution exists for decentralized water & wastewater treatment: electrocoagulation.

An emergent technology in water and wastewater treatment, electrocoagulation is more effective at removing many contaminants in one process.

This means it’s a better solution for improving water quality and meeting stricter effluent regulations in these applications.

However, to fully understand why that’s true, here’s everything you need to know about coagulation vs. electrocoagulation water treatment.

What is Coagulation Water Treatment?

Coagulants are chemicals you can use to eliminate suspended solids from water. These chemicals are positively charged molecules that help neutralize water. Examples of common types of coagulants include iron salts and aluminum, such as aluminum sulfate, ferric sulfate, ferric chloride, and polymers.

If you want to try coagulation, the process isn’t too complex. It happens before sedimentation and filtration and starts when you add a coagulant to water. Once added, the coagulant’s positive charge neutralizes the suspended contaminants’ negative charge, causing the suspended particles to bind together and become clumps known as “flocs.”

Flocs can be heavy, so they will sink to the bottom of the water supply and settle there, which is a process called sedimentation. Once the water is coagulated, it can be filtered through media filtration, or a microfiltration or ultrafiltration membrane to eliminate the settled particles.

What Does Coagulation Water Treatment Remove?

Coagulation can remove suspended solids and natural organic matter such as protozoa, clay, sand, gravel, iron, and bacteria. For the most part, these contaminants can change the color of water to orange or brown and also lead to an unpleasant taste, making it imperative to remove these hazardous particles.

However, some contaminants take longer to coagulate than others.

For example, sand and gravel can coagulate and neutralize within a couple of minutes, while protozoa and clay can take up to several hours. Algae and bacteria at certain diameters can take even longer to coagulate, totaling about eight days to sink to the bottom of the water supply during sedimentation.

Pitfalls of Chemical Coagulation Water Treatment

Even though coagulation is a standard water treatment method, it still has disadvantages. A primary pitfall is that chemical coagulation is an additive process. While the method helps to remove suspended solids, it achieves this goal by adding chemicals to the water. Adding these chemicals requires a complex procedure and extensive jar testing.

Additionally, the dosages of the conventional coagulants need to be incredibly precise to ensure the method works effectively. Often times, chemical coagulation forces you to continuously adjust the dosages based on the varying composition of the wastewater source and the coagulants or flocculants utilized.

Lastly, another major pitfall of conventional chemical coagulation is that it produces a significant volume of sludge that needs to be treated and dispose of, especially when using metal salts or synthetic polymers.

Also keep in mind that this sludge is typically hazardous because of these particular chemicals used therefore, increasing the disposal cost.

What is Electrocoagulation Water Treatment?

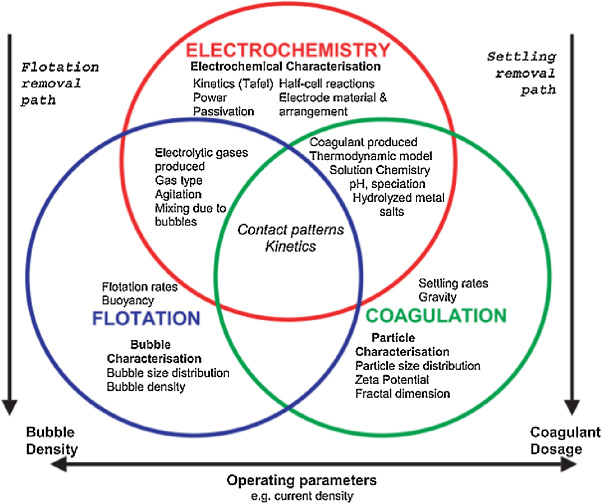

While electrocoagulation is a big word, it’s simple and incredibly effective at improving water quality especially in decentralized treatment application. This solution uses an electrochemical process that removes suspended, emulsified, or dissolved contaminants from water with an electric current.

Specifically, the current is supplied to various metal electrodes. The anodes go through oxidation, in which metal ions are released into the electrolyte. From there, the ions neutralize the charge of the solution, causing the contaminants to destabilize. The cathode also helps in the process by generating bubbles to assist in the flotation of the particles while the anodes are oxidizing.

Advantages of Electrocoagulation vs. Coagulation

The greatest thing about electrocoagulation is that it comes with many benefits. If you use this process for water treatment, you’ll notice the following advantages.

1. Offers a straightforward process

Electrocoagulation has few moving parts, so it’s a more straightforward process requiring less maintenance and oversight. It can also accommodate different amounts of particles without demanding much effort.

2. Increases water quality

Unlike coagulation, chemicals are not needed with electrocoagulation. However, a small amount of a sustainable clarification flocculant like Zeoturb can be useful in enhancing clarification post treatment.

In fact, research suggests that electrocoagulation “under the combined effects of aluminum and iron electrodes has elicited significant impact for the removal of organic matter, phenol, and color removal by 59%–76%, 70%–91%, and 70%–95%, respectively.”

3. Treats oily water

Traditional water treatment methods like coagulation can’t treat oily water. However, electrocoagulation technology is an effective treatment for oily water. When metal ions are released into the electrolyte, they destabilize the oil and water emulsion, forcing the oil droplets to merge and float to the surface to be clarified.

4. Reduces costs

With electrocoagulation, large quantities of contaminants are removed with a single system, and in certain cases, minimal recirculation time is required to achieve necessary contaminant reductions. This means it’s significantly more cost-effective than typical methods—the overall operating and capital costs associated with electrocoagulation are much less than chemical coagulation in many cases.

5. Produces less sludge

Another benefit of electrocoagulation is that it produces less harmful and smaller volumes of sludge. Since the method does not rely on conventional chemical additives, the sludge that electrocoagulation produces is easily dewatered, non-hazardous, and typically less costly to process and dispose of.

Use Cases for Electrocoagulation Water Treatment

Overall, electrocoagulation is a simple, economical, and environmentally-friendly choice. It’s an option for decentralized water & wastewater treatment for communities as well as industrial and commercial companies. For example, electrocoagulation can be helpful in the following cases:

Treating hospital wastewater

Treating refinery wastewater

Treating hotel grey water for reuse

Treating hard water

Of course, this is just a short list of use cases for electrocoagulation—this innovative method can be used for many different companies, industries, and communities. If you’re interested in utilizing electrocoagulation to treat your drinking water, process water or wastewater, reach out to experts like Genesis Water Technologies for assistance.