Natural Polymers for Industrial Flocculation

Imagine stepping into a world where the water is sustainably clarified. Not through magic, but science. The hero? Natural polymers for industrial flocculation. These aren’t your everyday materials. Derived from plant and marine life, they’re shaking up how we purify our most precious resource: water.

Flocculants have been around for ages, true. But synthetic options are so yesterday – expensive, harsh on the environment, and frankly, a bit old school. Enter natural polymers. Their cost is reasonable, and they are safer for the environment.

Based on recent studies conducted, they pack quite the punch in not only removing total suspended solids but also removing unwanted guests like COD, BOD and certain trace heavy metals such as chromium, nickel and copper from wastewater.

Skeptical? I was too until I saw them outperform their synthetic cousins under the microscope and in real-world applications in industries such as mining, food/beverage and manufacturing. These results were validated by an accredited third party US laboratory.

If reducing sludge production while improving water quality sounds like winning to you (because it should), then keep reading why natural polymers for industrial flocculation can be beneficial for your industry.

Table of Contents:

- Introduction to Natural Polymers in Industrial Flocculation

- The Science Behind Flocculation Mechanisms

- Evaluating Flocculation Efficiency and Mechanisms

- Factors Influencing the Flocculation Process

- Bio-Based Polysaccharide Flocculants for Water Purification

- Heavy Metal Removal Using Natural Polymers

- Advantages of Using Natural Polymers Over Synthetic Alternatives

- Practical Applications and Case Studies

- Choosing the Right Polymer for Your Industry Needs

- Future Directions in Water Treatment Technology Using Natural Polymers

- FAQs in Relation to Natural Polymers for Industrial Flocculation

- Conclusion

Introduction to Natural Polymers for Industrial Flocculation

Understanding the Basics of Flocculation, The Role of Natural Polymers in Water Treatment

Ah, flocculation. Sounds fancy, right? But let’s break it down. So, we’re essentially coaxing those minuscule particles suspended in liquid to gather up and take a chill pill. And who are we bringing into this mix? Natural polymers.

Natural polymers aren’t just any players; they’re like the eco-friendly superheroes of water treatment. Coming straight from nature’s playbook – think plants or marine life – these guys bring a lot to the table: They offer affordability, the ability to break down naturally, and minimal environmental impact.

- Lignin: Wood’s own natural polymer that shows up for heavy-duty cleaning.

- Tannins: They’re not just for making wine taste better; they also work wonders in water purification.

- Polysaccharides: These sugar chains mean serious business when it comes to clumping those unwanted particles together.

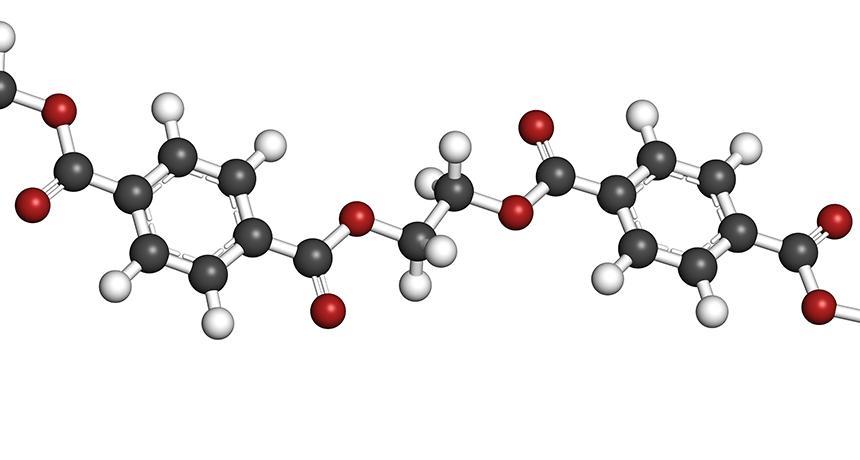

The real magic happens during the flocculation process. This is where things get clingy – but in a good way. By adding these natural polymers into the mix, we encourage small particles to become best friends and form larger clusters (flocs), which then gracefully sink to the bottom or get filtered out with ease.

This isn’t some high school science experiment either; its cutting-edge stuff happening right here and now in water and wastewater treatment facilities across the globe. With stats showing that natural polymer-based flocculants need variable dose rates typically from 30-100 mg/l based source water quality, they also offer improved shear stability (yep, you heard that right.). There’s no denying their potential for transforming how we handle water and wastewater effectively without harming our environment.

In essence? Next time you take a sip of crystal-clear water or appreciate clean rivers while hiking your favorite trail remember this: There could be some amazing chemistry powered by nature working behind the scenes as part of a treatment process ensuring every drop is as pure as it can be.

In Summary:

Discover the power of nature in water treatment with natural polymers like lignin, tannins, and polysaccharides. These eco-friendly superheroes help particles in water team up and settle down, making our rivers cleaner and our wastewater easier to treat without hurting the environment.

The Science Behind Flocculation Mechanisms

Charge Neutralization Explained

Ever wondered how nature tackles the mess in water? It’s all about balance, and charge neutralization is one key player. Think of colloidal particles as tiny rebels with an electric charge, causing chaos by refusing to settle down. Now enter our hero: a flocculant with the opposite charge.

This hero doesn’t fight; it hugs. When these oppositely charged characters meet, they neutralize each other’s charges. The result? Those once rebellious particles now start sticking together rather than pushing away from each other because their electric forces cancel out. This fascinating dance between charges is not just cool science; it’s vital for cleaning up our industrial process water and wastewater.

Polymer Bridging and Its Effectiveness

But wait—there’s more. Charge neutralization gets the party started, but polymer bridging turns it into a full-blown gala.

Polymer bridging happens when long-chain polymers act like bridges connecting several colloidal particles at once. Imagine holding hands with your friends in a crowded room; you’re much harder to push through as a group than alone. That’s what these natural polymer chains do—they create larger flocs by linking individual particles together.

The magic lies in this process making clarification easier since these larger flocs can be removed from water much faster than single small ones could ever dream of being settled or filtered out on their own.

In short:

- Charge Neutralization: Opposite charges attract, leading to particle agglomeration.

- Polymer Bridging: Polymer chains link multiple particles into bigger ones that are easier to remove—a real game-changer for improving water quality without breaking the bank or harming aquatic life.

Evaluating Flocculation Efficiency and Mechanisms

Determining Flocculation Performance, Key Mechanisms in Effective Flocculation

Let’s get real for a second. When we talk about flocculation efficiency, it’s not just some fancy term to throw around at dinner parties (unless you’re into that kind of thing). Delving into the essence of flocculation efficiency unveils the effectiveness of our purification methods, ensuring we’re not merely engaging in technical jargon but genuinely enhancing water quality. And who doesn’t want clean water, right?

So, here is the scoop: flocculation is all about getting those tiny particles in water to come together and form larger clumps – or flocs. Why? Because bigger clumps are easier to remove than single floating particles.

- The Removal Rate: Think of it as a game where your score goes up every time you catch a particle. Earning a higher score is indicative of enhanced efficiency in this context.

- Flocculation Mechanism: This is the strategy behind catching these particles—using natural polymers like starches or polysaccharides can be super effective because they’re sticky enough to pull this off without harming Mother Nature.

Beyond being eco-friendly, focusing on natural polymers for industrial flocculation such as Zeoturb takes us one step closer to making sure our water treatment isn’t costing the earth – literally and figuratively.

Delving into the significance of this, we uncover its profound impact on our pursuit of harmony with the environment. In simple terms, charge neutralization plays a big part here; think positive meets negative, creating balance. Then there’s polymer bridging — imagine throwing out multiple lifelines connecting stranded swimmers (particles) back together into safety (larger flocs).

To put it bluntly. If we nail down these mechanisms with high precision (yep, talking removal efficiency), then presto. We’ve got ourselves clarified water that is cleaner without emptying pockets on costly chemicals or hurting aquatic life with synthetic nasties.

Intrigued by how changing pH levels might boost your game even more? Or maybe wondering what role salt concentration has when playing in different waters? Stick around because I’m just getting started on peeling back layers from this onion.

In Summary:

Getting clean water hinges on mastering flocculation, where the goal is to turn tiny particles into big clumps for easy removal. Using natural polymers like starches, tannin or polysaccharides not only gets the job done but does it in an eco-friendly way. Remember, it’s all about charge neutralization and polymer bridging – that’s your ticket to clarified water that is cleaner without breaking the bank or harming nature.

Factors Influencing the Flocculation Process

The Impact of pH on Flocculation Efficiency

Let’s talk about pH, shall we? Imagine it as the mood of your water treatment party. Too acidic or too alkaline, and your guests (the particles) just won’t mingle right. The ideal pH is like setting the perfect ambiance—it makes all the difference in getting those particles to stick together.

In technical terms, the effectiveness of flocculation largely hinges on hitting that sweet spot in the pH range. Go too high or too low, and you mess with the charge balance needed for optimal particle attraction. Navigating the intricate ballet of attraction between positively charged coagulants and their negatively charged colloidal counterparts is akin to orchestrating a perfectly balanced symphony.

How Salt Concentration Affects Flocculation

Moving onto salt concentration—think of this as the social lubricant at our hypothetical party. Just enough can help break down barriers (or charges), letting our tiny particulate guests get closer than they otherwise would.

Salt affects flocculation by tweaking ionic strength, making it easier for polymer chains to bridge between particles. But here’s where it gets tricky; more isn’t always merrier when it comes to salt levels in water treatment processes.

- A pinch enhances aggregation but overdo it, and you risk reducing overall efficiency due to the increased competition among ions.

- Salt helps by compressing electrical double layers around suspended particles which encourages them to come together forming larger flocs—a key goal in effective water and wastewater treatment.

This intricate interplay between factors such as pH range and effect of salt shows how science merges with art in water treatment techniques. Every little adjustment has its role ensuring clarity doesn’t just remain an aspiration but becomes reality—for both industry professionals striving for excellence and communities relying on clean water daily.

In Summary:

Think of flocculation like a party where pH sets the mood and salt acts as the social lubricant. Get them right, and particles will mingle perfectly, leading to clear water. It’s a mix of science and art in getting every detail just so.

Bio-Based Polysaccharide Flocculants for Water Purification

Plants and their Role in Water Treatment

Nature has some pretty clever methods for purifying water, employing its own set of tricks. Let’s talk starch – not just for thickening your gravy anymore. This humble kitchen staple is taking the water treatment world by storm. These plant derivatives are making waves as eco-friendly flocculants that bind unwanted particles together so they can be easily removed from water. Why? Because they’re effective, affordable, and kinder to the planet.

The process is pretty straightforward but genius: When added to murky water, starch grabs hold of those tiny troublemakers causing all the cloudiness and clumps them into larger particles that settle down or can be filtered out. Simple yet powerful.

Studies show that modified plant derivatives aren’t just good; they’re great at this job under various conditions.

Polysaccharides as a Natural Coagulant

Moving over from pantry staples to marine life waste – yes, you heard right. Polysaccharide derivatives can come from plant and marine life. They’re another superstar natural polymer stepping into the spotlight for water and wastewater treatment.

This stuff works wonders with heavy metals and dyes – latching onto these pollutants like a magnet does with iron filings. The best part? This enchantment unfolds as it purifies without introducing any toxic substances into the equation.

We’re talking clean water coming through an environmentally gentle process, folks.

If we zoom in on what makes certain polysaccharides stand out: It’s positively charged while many pollutants carry a negative charge.

The result? Opposites attract, allowing these specific materials to effectively pull contaminants out of suspension, leaving behind clearer, purer water.

So there you have it—starches bulking up their resume beyond pie fillings and gravies while polysaccharide-derived polymer solutions such as Zeoturb allow for greener endeavors in water & wastewater management.

In Summary:

Plant starches and Polysaccharides are rocking the water treatment scene, turning kitchen staples and marine life waste into eco-friendly heroes that tackle pollutants head-on. Simple, effective, and enviromentally friendly – these natural polymers are proving to be game changers in keeping our water clean sustainably.

Heavy Metal Removal Using Natural Polymers

Techniques for Removing Heavy Metals from Wastewater

Gone are the days when heavy metal in your life only referred to a genre of music. Now, it’s about something much more serious – pollutants in our water and wastewater. But fear not, because nature has got our back with natural polymers stepping up as eco-warriors in the battle against heavy metal ions in industrial water treatment.

Several case studies shows that these green heroes like plant starches and polysaccharides can bind with trace metals faster than you can say “contamination”. Let’s break down how they do this magic, shall we?

- The Chelation Station: Imagine each polymer as a tiny magnet. They attract and hold onto metals thanks to their special functional groups (like amino or hydroxyl). This is called chelation – think of it as giving heavy metals a bear hug they can’t escape from.

- Bridging The Gap: Then there’s bridging – where one end of a polymer chain grabs onto one particle and another part latches onto another, pulling them together into larger flocs. It’s like introducing two friends who then decide to throw a party; suddenly everyone wants to join.

- Flocculation Nation: These bigger parties (or flocs) are easier for us to remove through settling or filtration. So essentially, natural polymers turn unwelcome guests into something we can easily shove out the door.

We’re not just talking theory here; practical applications have shown stellar result for the treatment of trace metals including iron, chromium, nickel among others. For example, plant starch juices (yep, you read that right,) boast an impressive ability at snagging those pesky metal ions out of wastewater.

In fact, our experiences have demonstrated that combining biopolymers with electrocoagulation technologies or reactive catalyst technologies. This could form super teams that boost both efficiency and cost-effectiveness when dealing with mixed contaminant scenarios —-Talk about teamwork making the dream work.

In Summary:

Nature’s polymers are like eco-warriors, using chelation and bridging to tackle heavy metal pollution. They transform pollutants into easy-to-remove flocs, showing that going green can also mean being clean.

Advantages of Using Natural Polymers Over Synthetic Alternatives

Benefits of Natural Polymers in Reducing Treatment Costs

Ladies and gentlemen, gather around. Let’s talk about something that doesn’t get the spotlight it deserves – natural polymers. These overlooked champions, beneficial for both our environment and budget in water purification endeavors, rarely receive the acclaim they merit.

Why go natural? Well, first off, these eco-friendly alternatives come from renewable sources like plants derivates or polysaccharides. Thus, we avoid depending upon upon fossil fuels in their creation. But here’s where it gets really interesting: They can significantly slash water treatment costs.

- Biodegradability: Unlike their synthetic counterparts, natural polymers break down easily without harming Mother Nature. Less environmental cleanup equals less money spent on damage control.

- Efficacy at lower doses: They often work more efficiently than synthetics meaning you use less product over time—a clear win for budget-conscious operations.

- Sludge savings: Derived from natural substances, biopolymers create sludge solids that are easy to dewater reducing sludge disposal costs over synthetic polymers and metal salts.

- With advancements in science making these natural wonders even more effective; the only “catch” is why we didn’t make the switch sooner.

A shining example lies within industries battling heavy metals in wastewater (source). Polysaccharides have shown stellar performance in capturing those pesky metal ions while being kinder to both nature and budgets alike.

In essence, by opting for natural polymers in your water treatment processes, you’re investing in sustainable practices that promise not just immediate financial benefits through cost reduction but also long-term gains by preserving our ecosystem’s health—making sure clean water remains a reality for generations to come.

And isn’t that worth every penny?

The bottom line? Improving water quality improvement, reducing process water and wastewater treatment costs, safeguarding biodiversity—it seems going green with your flocculation process checks all boxes. So next time you weigh options between synthetic versus organic flocculants/coagulants remember: Going green could mean saving some serious green too.

In Summary:

Switch to natural polymers for water treatment. They’re eco-friendly, cut costs by working efficiently at lower doses, with lower sludge disposal costs. Plus, they protect our environment and pocket.

Practical Applications and Case Studies

Real-World Examples of Successful Natural Polymer Use

You might be thinking, “Okay, natural polymers sound cool and all, but do they actually work outside the lab?” Let’s talk real-world success stories that’ll make you a believer.

Natural polymers aren’t just some fancy science experiment. In the thick of it, natural polymers are purifying water and bringing smiles to industrial faces. From pilot-scale tests to full-on industrial showdowns, these bio-based heroes are showing up synthetic alternatives big time.

- Pilot-Scale Test: Picture this – a food/beverage company struggling with TSS, COD, BOD in their wastewater . Enter stage left: Zeoturb, our biopolymer protagonist. Not only did it reduce turbidity by over 90%, but it also cut down COD levels significantly—all at doses lighter than a feather on your palm.

- Full-Scale Test: Then there’s the case of a mining operation and steel production operation where heavy metals were crashing the party hard. The Zeoturb biopolymer stepped up again—this time removing upwards of 99% of those uninvited metal ions like chromium and lead. Talk about gatecrashing.

The best part? These aren’t isolated incidents or one-hit wonders according to several case studies. All across the globe—from small town operations to sprawling urban treatment plants—natural polymers are proving their mettle (or should we say ‘metal’?).

Surely by now you’re asking yourself why anyone would still stick with synthetic flocculants when nature offers such powerful solutions that are not only effective but kinder to our planet too.

If these examples have got your gears turning on how natural polymers can revolutionize water treatment in your industry, then my job here is done—for now.

Choosing the Right Polymer for Your Industry Needs

Factors to Consider When Selecting a Polymer

You’ve got this. Picking the right polymer isn’t rocket science, but it sure feels like it sometimes, doesn’t it? Let’s break it down into bite-sized pieces that won’t give you a headache.

The first step? Chat with an experienced application engineer. Tap into the expertise of these water treatment professionals, who will navigate you through the complexities to identify precisely what your setup demands. They’re like your personal GPS in the world of polymers—trust them to lead the way.

But wait, there’s more. The real magic happens during lab scale treatability testing where they’ll figure out which polymer chemistry fits best for your application. It’s all about finding that perfect match—the one that meets regulations without breaking the bank.

- Type matters: Are we talking dry or liquid polymers here? Selecting between options influences not only the price but also the machinery requirements and how long your products will remain active.

- Anionic vs Cationic: Think about who you’re inviting to this party—is it mostly inorganic solids or something else? Your industry dictates whether anionic or cationic pals are coming over.

- Dosing Equipment Costs: Not all gear comes with the same price tag. Factor in how much juice (aka polymer) your process requires and whether any performance gaps need bridging.

Sure, navigating through options might seem daunting at first glance—but think of this as assembling a puzzle where every piece plays its part perfectly once found.

In essence, selecting just-the-right polymer isn’t merely ticking boxes off a checklist; it’s about ensuring harmony between costs, efficiency and sustainability within your unique ecosystem—a task undoubtedly crucial yet entirely achievable with a bit of guidance and insight.

Future Directions in Water Treatment Technology Using Natural Polymers

Emerging Trends and Innovations

The world of water treatment technology is always on the move. Just when you think it’s all been done, a new innovation pops up, turning heads and stirring the pot. And right now, natural polymers are leading the charge.

Diving into the realm of these bio-based marvels, it’s clear they’re not merely fleeting fancies but rather a glimpse into a future where our water is purer and more sustainable for all.

- Eco-friendly materials: We’re seeing more companies lean towards using natural polymers like chitosan and starch derivatives. Why? Because they tick all the boxes – effective, sustainable, and gentle on Mother Nature.

- Slick tech meets nature: Imagine combining cutting-edge tech with ancient wisdom from nature’s own toolkit. That’s where we’re headed with advanced modifications to these polymers that enhance their performance under varied conditions.

- Tailor-made solutions: One size doesn’t fit all in water treatment. The buzz is around choosing biopolymer to target specific contaminants or processes – truly bespoke solutions for complex challenges.

- Beyond wastewater: While cleaning up industrial effluent is huge, there’s plenty of potential elsewhere too—like purifying drinking water, process water or even recovering precious metals from mining runoff using natural flocculants.

This isn’t just wishful thinking; it’s happening as we speak. For instance, natural polymers like Zeoturb are being used across both industrial and municipal water treatment applications.

So what does this mean for industries across the board?

In short: A lot. With every step forward in utilizing natural polymers for water treatment technology advancements, we’re looking at safer environments and better health outcomes globally. This is not to mention overall cost savings by up to 30% or higher in operations thanks to efficiency boosts and reduced sludge disposal costs provided by these innovations.

It goes beyond merely keeping our waters clean; it’s about reshaping how industries relate to our planet’s most precious resource while embracing growth opportunities presented by emerging trends. Now that’s something worth diving into.

Feel free to reach out if you have any questions or want to discuss the future possibilities of natural polymers. Chatting about the potential of natural polymers always gets me buzzing with enthusiasm.

In Summary:

Natural polymers are changing the game in water treatment, offering eco-friendly, customizable solutions that combine cutting-edge tech with nature’s wisdom. This isn’t just about cleaner water—it’s a step towards a greener future for our environment and industries.

FAQs in Relation to Natural Polymers for Industrial Flocculation

What polymers are used as flocculants?

Synthetics polymers like polyacrylamide and natural polymers such as polysaccharides get the job done by clumping particles in water.

What are natural flocculant examples?

Moringa seeds, starches, polysaccharides, and lignin are some examples of making water clear without harsh chemicals.

What is the best synthetic chemical for flocculation?

Polyacrylamide performance well in snagging tiny particles out of wastewater.

What polymer is best for wastewater treatment?

In treating contaminated water, polysaccharides perform well. They are safe, effective, and love nature as much as we do.

Conclusion

So, there you have it. The world of water treatment might not seem like the backdrop for an epic saga, but throw natural polymers for industrial flocculation into the mix, and suddenly we’re in a story worth telling. Gone are the days when synthetic chemicals or inorganic metal salts held the throne; now, it’s all about these eco-friendly warriors.

Embarking on this scientific odyssey has been akin to uncovering a spell book, where flora and fauna emerge as valiant champions in our crusade towards pristine water. Not merely theoretical marvels, these organic polymers are transforming both experimental and practical realms. They slash expenses, nurture our world, and can efficiently dispatch suspended solids, hazardous trace metals and other particular contaminants.

This isn’t just another chapter in water treatment history – it’s a revolution. And guess what? You’re part of it every time you choose sustainability over synthetics. Remember this: as much as we’ve learned today about clearing up wastewater with nature’s help, there’s always more to explore tomorrow.

Feeling accomplished yet? Armed with what we’ve uncovered today about purifying wastewater naturally, you ought to feel empowered, for knowledge is a formidable ally in safeguarding our invaluable water.

Therefore, choose natural polymers for industrial flocculation and be a part of the solution to cleaner water and a healthier environment. Embrace sustainability over synthetic polymers conventional commodity metal salts and empower yourself with knowledge to safeguard our invaluable water resources. Together, let’s make a difference for generations to come.

Want to learn more about how natural polymers such as Zeoturb bio organic flocculant can help optimize your industrial water treatment clarification process? Contact the water & wastewater treatment experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or reach out to us via email at customersupport@genesiswatertech.com to discuss your specific situation.