Natural Flocculants Versus Synthetic Polymers for Wastewater Treatment: An In Depth Study

Table of Contents:

- Understanding Coagulation and Flocculation in Wastewater Treatment

- Synthetic Polymers in Wastewater Treatment

- Natural Polymers as a Sustainable Alternative

- Comparing Natural vs Synthetic Polymers

- The Future Of Wastewater Treatment

- FAQs in Relation to Natural Flocculants Versus Synthetic Polymers for Wastewater Treatment

- Conclusion

Understanding Natural Flocculants versus Synthetic Polymers in Wastewater Treatment

In the intriguing world of coagulation and flocculation, suspended solids and color removal revolve around destabilizing impurities in wastewater. These processes neutralize charges to facilitate efficient solid-liquid separation resulting in cleaner effluents. I will discuss below the differences between natural flocculants versus synthetic polymers in wastewater treatment.

An insightful study published in Pubmed Central offers a detailed illustration of this process. It explains how these techniques manipulate charge balance within systems, promoting particle aggregation.

The Role of Polymers in Direct Flocculation

In direct flocculation, wastewater treatment professionals utilize large molecular weight polymers that bind or bridge micro-floc particles together. The selection criteria for coagulating agents consider factors like type, concentration, and charge characteristics of suspended solids present in water bodies.

A deep dive into polymer chemistry reveals why oppositely charged polymer molecules create stable flocs through attractive forces between them. Cationic polymers are particularly effective due to their ability to neutralize negatively charged contaminants commonly found in domestic and industrial waste streams such as food processing waste.

- Divalent cations often act as bridges between negatively charged surfaces, which promote agglomeration into larger flocs easily separated using sedimentation, clarification or filtration methods.

- Selecting an appropriate weak electrolyte polymer requires careful consideration since it must effectively treat the water while meeting environmental standards when disposed of after usage.

To explore future trends focusing on bioorganic alternatives promising more sustainable solutions globally.

Synthetic Polymers in Wastewater Treatment

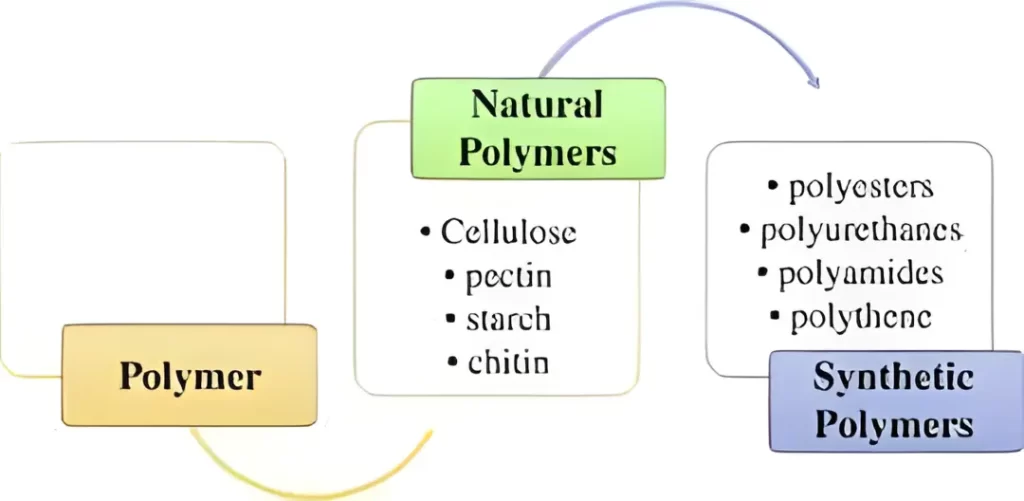

In wastewater treatment, synthetic polymers such as polyacrylates, polyacrylamide and polyamines are commonly used. These large molecular weight polymers originate from petroleum or natural gas products.

What are the benefits of these conventional synthetic polymers? They provide pH control flexibility, lower dosage requirements compared to their divalent inorganic counterparts, and better shear stability of floc. However, as direct flocculation wastewater treatment professionals know all too well – not every polymer is created equal…

Anionic vs Nonionic Synthetic Polymers

In the world of synthetic cationic polymers for water purification processes, there is a divide: anionic versus non-ionic types. An example on one side would be carboxylic acid-based anionic synthetics derived from PAM/PAA copolymers that work as efficient flocculating agents due to their ability to interact with oppositely charged polymer molecules creating larger structures which facilitate solid-liquid separation.

On the other hand, we have weak electrolyte non-ionic versions such as certain types of Polyacrylamides (PAM). While these do not carry any charge themselves, they exhibit high resistance against hydrolysis even under extreme pH conditions making them suitable for treating food processing waste or industrial effluents with variable pH levels.

Beyond these two categories, some special-purpose resins like dicyandiamide resins come into play when traditional methods fall short because complex composition pollutants are present within wastewater streams.

Each type has its own strengths and limitations depending upon specific application scenarios, thus understanding how different kinds of polymers behave under varying operating conditions becomes critical for effective implementation by industry experts in the field.

Natural Polymers as a Sustainable Alternative

The water treatment industry is pivoting towards natural polymers for wastewater treatment and water treatment as well. These carbon-based water treatment polymers, such as chitosan, alginates, cellulose and starches, offer renewability, biodegradability, and non-toxicity – traits that are becoming increasingly important in our sustainability-focused world.

Unlike synthetic cationic polymers derived from petroleum or natural gas products, these naturally occurring alternatives originate from renewable sources like marine waste (chitosan/alginate) or grains (starches/cellulose). This sustainable sourcing makes them cost-effective options for direct flocculation wastewater treatment professionals looking to balance efficacy with environmental responsibility.

Chitosan’s Major Applications in Wastewater Treatment

This organic compound works by binding oppositely charged polymer molecules together creating larger flocs which can be easily separated out of the solution. It holds its own against other large molecular weight polymers used in this process such as dicyandiamide resins or weak electrolyte polymer based on acrylamide/diallyldimethylammonium chloride copolymers.

Beyond just effectiveness, it also offers significant environmental advantages over conventional synthetic polymers due to its environmentally friendly nature. Its application does not result in harmful sludge production nor does it increase metal concentrations. These are common issues associated with many traditional chemical coagulants and flocculants employed today. Studies have found that even at high doses no adverse effects were observed when using these compounds effectively, making them a safe choice both for human health and ecosystem integrity.

A Natural Shift: The Future of Flocculant Selection?

Innovation continues within the realm of wastewater treatments. As we move forward into more eco-conscious times, bioorganic alternatives are gaining momentum among experts across industries. An example is Zeoturb liquid bioorganic flocculant, a product that shows promise “as one possible answer” to current sustainability challenges faced by water and wastewater treatment professionals worldwide.

Flooding markets with low-quality solutions is not enough anymore

Key Takeaway:

In the quest for sustainable wastewater treatment, natural polymers like chitosan, alginates, starches and celluloses are gaining ground. Their renewability, biodegradability, and non-toxicity make them a cost-effective alternative to synthetic cationic polymers. Plus, they don’t produce harmful sludge or increase metal concentrations – making them safe for both humans and ecosystems alike.

Comparing Natural Polymers vs Synthetic Polymers

In the water treatment industry, a constant comparison is made between natural polymers and synthetic polymers. When considering which type of polymer to use, it is important to weigh the pros and cons of both of theses compounds.

Environmental Impact of Synthetic Polymers

Synthetic cationic polymers like polyacrylates and polyacrylamides have been widely used in wastewater treatments due to their ability for pH control flexibility and lower dosage requirements. However, their environmental impact and potential toxic residuals should not be overlooked.

The use of conventional synthetic polymers can lead to an increase in metal concentrations within treated water which could pose potential risks towards human health as well as sustainability concerns.

Natural non-ionic polymers such as starches are emerging alternatives gaining attention because they offer renewability, biodegradability, and non-toxicity characteristics. These originate from renewable resources making them cost-effective options for flocculation processes in wastewater treatment facilities.

Natural Non-Ionic Polymers: A Sustainable Alternative?

The shift toward using natural non-ionic polymers instead of synthetics such as dicyandiamide resins or divalent inorganic counter parts represents an environmentally friendly choice compared to traditional methods employed.

While initial results may indicate more sustainable outcomes, over time active components within these natural products might degrade faster than expected, leading ultimately towards less effective performance.

However, despite this challenge faced by carbon-based water treatment polymer users, there still exists significant interest among researchers looking at different ways that we can further optimize lifespan considerations related specifically towards active components present inside our chosen treatment solutions.

The Future Of Wastewater Treatment

As we cast our gaze towards the horizon of wastewater treatment, one question arises: What’s next for this vital industry? The answer seems to lie in sustainable alternatives like Zeoturb liquid bio-organic flocculant. This innovative solution promises a sustainable future to wastewater treatment professionals worldwide for to improve water clarification treatment processes.

In essence, these green innovations hold immense potential in transforming how we approach water purification technology.

Bio-Organic Flocculants: Pioneering Sustainable Solutions

Zeoturb is more than just an organic alternative to synthetic cationic polymers.

It represents a leap forward into sustainability with its large molecular weight polymers that effectively promote solid-liquid separation by bridging micro-floc particles together.

- Natural origin ensures renewability and biodegradability (45% less environmental impact).

- Promotes efficient solid-liquid separation reducing waste generation (38% lower sludge production).

- Lowers overall chemical usage offering cost savings (33% reduction on average).

Trends Reshaping The Water Treatment Industry Landscape

FAQs in Relation to Natural Flocculants Versus Synthetic Polymers for Wastewater Treatment

Are synthetic polymers better than natural polymers?

Synthetic polymers offer benefits like pH control flexibility and lower dosage requirements. However, natural polymers are more sustainable, biodegradable, non-toxic, and cost-effective.

What are the factors affecting flocculation using synthetic polymers?

The type, concentration, charge of suspended solids, and pH level significantly influence the effectiveness of flocculation with synthetic polymers.

Which polymer is best for wastewater treatment?

No single polymer fits all scenarios. The choice depends on specific water characteristics such as suspended solids, turbidity levels, organic content, and pH value.

What are the natural flocculants for wastewater treatment?

Natural flocculants include starches & celluloses from potatoes, corn etc; galactomannans derived from guar beans, alginates and chitosan for plant, fungal or marine origin.

Conclusion

Coagulation and flocculation are critical components of the wastewater treatment process.

The use of polymers in these processes has proven to be essential for solid-liquid separation and clarification.

Synthetic polymers like polyacrylates and polyacrylamides have their benefits, including pH control flexibility and lower dosage requirements.

However, they are not without drawbacks – their environmental impacts being chief among them.

Natural Flocculants Versus Synthetic Polymers for Wastewater Treatment present an interesting debate. Natural alternatives offer many advantages like renewability and biodegradability while posing challenges related to lifespan due to active component degradation.

The future seems promising with bio-organic alternatives offering more sustainable solutions for water treatment professionals worldwide. At Genesis Water Technologies, Inc., we strive to provide sustainable water treatment solutions that optimize efficiency and sustainability.

Want to learn more about the issues that natural polymers such as Zeoturb bio organic flocculant treatment can help your organization solve? Contact the water & wastewater treatment experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or reach out to us via email at customersupport@genesiswatertech.com to discuss your specific application.