How to Make Wastewater Treatment Flocculation Sustainable, Non Toxic, and Efficient

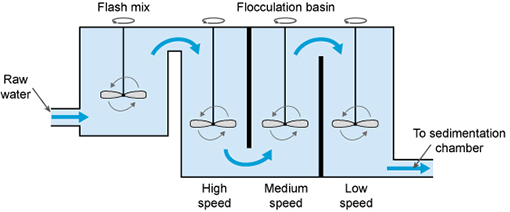

If you manage a water treatment plant or consult those who do, you know wastewater treatment flocculation is essential to delivering clean, safe, and reliable water. Following coagulation water treatment, flocculation encourages small, suspended particles in water to clump together into flocs, making them easy to be removed by post filtration.

However, although flocculation helps remove suspended solids from a water supply, the process is not always sustainable, non-toxic, and efficient.

The reason? The flocculation water treatment your utilizing or recommending may not achieve the best results, primarily because of the synthetic polymers and metal salts used.

The Negative Effects of Synthetic Polymers and Metal Salts

It’s common to use polymers to improve flocculation water treatment. These molecular compounds can increase and strengthen the weight of flocs to make them easier to separate from drinking water, process water and wastewater. However, the problem with most polymers is that they’re synthetic, resulting in a host of negative effects.

Synthetic polymers are essentially derived from hydrocarbons, a toxic origin that lends to a toxic result. When you combine this with conventional metal salts that are often used in coagulation water treatment, delivering clean, safe, reliable water is incredibly difficult. When metal salt coagulants are used, residuals remains in the water after treatment, leading to potential diseases and negative environmental impacts.

Still, the toxicity of synthetic polymers and metal salts isn’t the only reason why flocculation wastewater treatment may be missing the mark when it comes to improving water quality. These agents are also unsustainable and inefficient for the following reasons:

Sludge volume and dewatering ability: They produce a high sludge volume and require complex dewatering.

Sludge disposal costs: Synthetic polymers and metal salts have high disposal costs. Also, this solid sludge is typically categorized as a hazardous substance and must be disposed of in accordance with specific regulations.

Residual metal ions in treated water: Aluminum and iron salts both remain in treated water. High levels of aluminum can affect the human body and lead to bone pain, various non-healing fractures, muscle weakness, and more. Iron salts also impact the color of water, producing a reddish-colored tint.

Reduction of disinfection byproducts in treated water: Synthetic polymers and salt metals are less effective in removing organic compounds, humic and tannic acids, and suspended solids that cause DPBs when interacting with chlorine for post filtration disinfection processes.

Decrease in trace metals: A combination of synthetic polymers and salt metals must be used to reduce trace metals—one isn’t enough.

Contaminants in wastewater: In wastewater, only turbidity, total suspended solids, and organic matter are decreased. Also, synthetic polymers and metal salts are less effective at reducing color, BOD, COD and certain trace metals.

Cost of usage: The material expense is typically inexpensive for conventional metal salts, which seems cost-effective. However, the total price of treatment, including the cost associated with increased sludge volume and hazmat sludge disposal fees, increases expenses significantly. Fees can also incur because of the potential health and environmental effects synthetic polymers and conventional metal salts deliver.

With synthetic polymers and conventional metal salts carrying so many negative effects, it’s worth considering ways to improve the flocculation water treatment process. Fortunately, there is a solution to make flocculation non-toxic, sustainable, and efficient.

How to Improve Flocculation Water Treatment

Synthetic polymers are not the only options available for flocculation water treatment. Natural polymers exist as well, and they are sustainable, non-toxic, and efficient.

For example, Genesis Water Technologies developed the GWT Zeoturb Bio-Organic Liquid Flocculant. It’s composed of marine biopolymer, meaning it’s derived from marine life, so it’s natural and sustainable.

Additionally, the natural polymer in the GWT Zeoturb Bio-Organic Liquid Flocculant performs better than synthetic polymers, making it a more efficient option.

Also, other factors can showcase the non-toxic, sustainable, and efficient aspects of the natural polymer used in the GWT Zeoturb Bio-Organic Liquid Flocculant.

Some of those factors include the following:

Sludge volume and dewatering ability: There’s lower sludge volume and an easy dewatering process.

Sludge disposal costs: The costs of disposing of a natural polymer is lower. Also, the solids pass TCLP protocols for land application and, in some cases, domestic wastewater application.

Residual metal ions in treated water: When using the GWT Zeoturb Bio-Organic Liquid Flocculant, there are no residual metal ions remaining in treated water.

Reduction of disinfection byproducts in treated water: With the natural polymer in the GWT Zeoturb Bio-Organic Liquid Flocculant, there’s a significant reduction of organic compounds and suspended solids that cause DPBs when interacting with chlorine.

Decrease in trace metals: There’s a major reduction in trace metals, including Fe, Ni, and Cu.

Contaminants in wastewater: The natural polymer in the GWT Zeoturb Bio-Organic Liquid Flocculant will reduce multiple contaminants in wastewater, including total suspended solids, turbidity, trace metals, BOD, color, COD associated with color, smell, odor, and hydrogen sulfide.

Cost of usage: The cost of Zeoturb is cmparative to synthetic polymers and there is no coagulant typically required. However, cost will vary based on water quality and dosage rates. Additionally, because the sludge volume and disposal costs are lower, the wholistic price is at least 30% less than synthetic polymers and metal salt coagulants. Lastly, natural polymers’ environmental compatibility prevents potential ecological costs from incurring.

Natural polymers are the best way to enhance flocculation water treatment and provide drinking, domestic, and industrial water that meets regulations and is safe and clean. Therefore, if you are a plant manager or an engineering consultant committed to effectively treating wastewater, start shifting your focus to wastewater treatment flocculation with natural polymers.

GWT Zeoturb Bio-Organic Liquid Flocculant is a treatment solution that you can utilize to optimize your water clarification results.

Our team is composed of water and wastewater experts to assist you in deploying this solution to remove contaminants in a sustainable, non-toxic, and efficient way.

To learn more about how the GWT Zeoturb Bio-Organic Liquid Flocculant can be used in your application, call us at +1 877 267 3699 or email us at customersupport@genesiswatertech.com. We look forward to helping improve your flocculation water treatment to ensure you meet your water treatment goals.