Reverse Osmosis in Industrial Wastewater Treatment, How Can It Play a Priority Role?

This question often comes to mind when discussing sustainable wastewater management and reuse strategies for industrial client applications. The truth is, understanding the role of reverse osmosis in treating industrial wastewater can be quite complex. Grasping this concept is not a task that can be completed quickly.

But here’s the deal…

Without grasping this concept, industrial clients may not fully optimize their waste management systems or maximize their sustainable water resource initiatives.

Talking about how reverse osmosis plays a pivotal part in industrial wastewater treatment is not merely technical jargon—it’s crucial for our environment and future generations to optimize water resources!

Table of Contents:

- Understanding Reverse Osmosis in Industrial Wastewater Treatment

- The Process of Reverse Osmosis in an Industrial System

- The Impact of Reverse Osmosis on Water Quality Industries

- Benefits and Cost Savings with Reverse Osmosis Water Treatment

- Challenges and Misconceptions About Using Recycled Water

- FAQs in Relation to How Does Reverse Osmosis Play a Role in industrial Wastewater Treatment

Understanding Reverse Osmosis in Industrial Wastewater Treatment

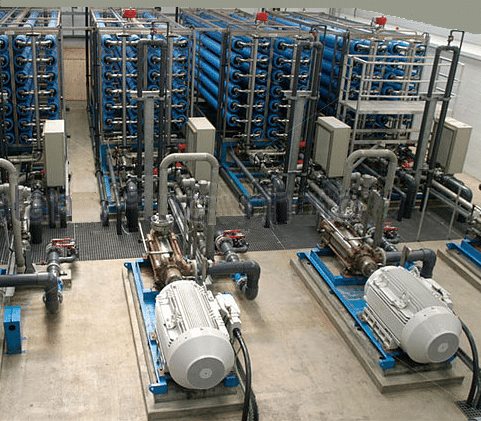

In the sphere of industrial wastewater treatment, reverse osmosis is a key player. A semi-permeable membrane functions as a barrier, barring waterborne impurities from passing through. Through the application of pressure, reverse osmosis forces water through this selective filter to remove up to 99%+ of dissolved salts, particles, colloids, and bacteria.

This filtration method generates two streams: permeate (the product) and concentrate (waste). The ratio between these outputs represents the system’s efficiency ”known as its recovery rate” and high-quality RO systems often attain impressive ratios based on the source water salinity levels.

The Role of Reverse Osmosis in Ensuring Sustainability

Beyond just purification benefits within industries themselves, reverse osmosis technologies minimize the release of contaminated waters back into our ecosystems through its ability to polish and treat wastewater for reuse or utilize substandard water sources for industrial process water applications. In doing so, they contribute towards improving local water quality through minimized discharge ”a feat which means much more than simply adhering to regulatory standards; it signifies active participation in global efforts toward sustainability amidst rapidly diminishing resources worldwide.

Economic Advantages & Regulatory Compliance with RO Systems

It’s clear then that when used appropriately within an industrial context, reverse osmosis offers tremendous benefits both economically, technically and environmentally.

The Process of Reverse Osmosis in an Industrial System

It all starts with the pre-treatment stages, where mechanical and chemical treatments are applied to prevent fouling and scaling on RO membranes.

Importance of Pre-treatment for the Reverse Osmosis Process

In any reverse osmosis system, proper pre-treatment holds significant value in maintaining operational efficiency. This process helps avoid issues like fouling, scaling, or premature failure of membranes, which leads to high operating costs and could lead to costly downtime.

Commonly used methods include sedimentation or clarification wih flocculants or coagulants during this stage to remove larger suspended solids from water while reducing hardness and other potential mineral contaminants. Flocculants such as Zeoturb can be used in clarification and specialized antiscalants can be added directly into the feed water stream just before the RO treatment process to minimize its potential for causing mineral buildup on the membrane surface.

Maintaining Performance with Regular Membrane Cleanings

- Cleaning frequency typically ranges between 1-4 times annually depending upon factors such as raw water quality and usage rates.

- This involves flushing out accumulated contaminants inside the membrane modules using specially formulated solutions designed not only to clean but also to preserve the integrity of these technologically advanced systems.

- A consistent upkeep routine significantly extends your system’s lifespan while ensuring you continue reaping the benefits associated with high-quality purified process water provided by reverse osmosis technologies.

- Finally, using a programmable permeate flush function can also reduce membrane cleaning frequencies significantly.

The Impact of Reverse Osmosis on Water Intensive Industries

Reverse osmosis is an effective tool for the tertiary treatment of industrial wastewater, enabling these sectors to prevent releasing contaminated water back into our environment.

This is not just about improving local water quality – it goes beyond that. It has implications for public health and sustainability of natural resources too.

Statistics show that industry players using reverse osmosis technology have achieved up to 90 percent savings in their wastewater through internal treatment processes. That’s quite significant given the amount of waste generated by large-scale operations every day.

Sustainable Management with Reverse Osmosis

Incorporating reverse osmosis systems within industry practices can be seen as partaking in sustainable management strategies. These technologies allow companies not only to reduce their ecological footprint but also ensure operational efficiency simultaneously.

Treated wastewater does not end up wasted; instead, it gets reused internally or safely discharged without posing risks to either aquatic life or human health – all thanks to technologically advanced membrane systems used during the tertiary treatment process.

Promoting Environmental Stewardship

Industries adopting this technology are taking responsibility towards environmental stewardship far beyond regulatory compliance requirements alone. They’re making strides toward building a greener future where clean, safe drinking water is abundant rather than scarce.

Research published by National Center For Biotechnology Information (NCBI), suggests such businesses enjoy improved market reputation which typically translates into increased sales opportunities over time due to its positive impact on stakeholders including customers, investors, and employees alike who appreciate efforts made toward preserving natural resources for future generations.

Benefits and Cost Savings with Reverse Osmosis Water Treatment

The integration of reverse osmosis in industrial wastewater treatment brings about numerous advantages. One notable benefit is the significant cost savings from reduced water usage in regions where water is scarce, while another is improved plant’s water security by treating wastewater internally.

Environmental Stewardship through Improved Local Water Quality

A key aspect of employing reverse osmosis technology lies in its ability to purify process water effectively as well. This not only meets operational needs but also significantly contributes towards improving local water quality.

This approach minimizes the release of contaminated waters back into our environment, playing a crucial role in sustainable management practices for rapidly diminishing global freshwater resources. It’s more than just meeting environmental regulations; it’s about demonstrating corporate responsibility and commitment to creating a more sustainable future.

Becoming Industry Leaders Through Sustainable Practices

In today’s competitive market landscape, adopting innovative solutions like using sustainable pretreatment solutions along with reverse osmosis for industrial wastewater treatment can set industrial companies apart as leaders in their industries for sustainability initiatives. These actions do not merely yield direct financial benefits due to lower operating costs – they position companies at the forefront of their respective sectors.

Making these strides has far-reaching implications: enhancing public perception, increasing customer loyalty towards brands that prioritize environmental stewardiness, and even potentially boosting sales figures because consumers are increasingly drawn toward businesses that show concern for their ecological footprint. Discover how Genesis Water Technologies’ advanced membrane systems can help your business make this leap forward – delivering both economic value and reducing ecological impact concurrently.

Challenges and Misconceptions About Using Recycled Water

The topic of recycled water often stirs up a fair amount of controversy. Despite the thorough purification processes it undergoes, such as reverse osmosis, there are still widespread misconceptions about its safety and cleanliness.

Overcoming Challenges With Advanced Technologies

In an industrial system that treats wastewater internally, how can we overcome these challenges? The answer lies in leveraging advanced technologies like sustainable flocculants and treatment media in pretreatment such as Zeoturb and Natzeo treatment media. This would be followed by technologically advanced membrane systems which have revolutionized the way we treat wastewater by enhancing efficiency and reliability.

A particular example is reverse osmosis technology. It not only purifies process water but also significantly reduces contaminants in treated industrial wastewater before release into a local ecosystems or reuse within facilities. This has made it possible for industries to tackle key challenges associated with recycling wastewater while ensuring compliance with stringent environmental regulations.

Debunking Myths About Recycled Water

Moving on to another challenge – debunking prevalent myths surrounding recycled water’s quality and safety standards. Contrary to popular belief, properly treated recycled water isn’t inferior or unsafe compared to conventional freshwater sources.

- This misconception stems from a lack of understanding about how effective purification technologies like reverse osmosis can be when implemented correctly within an industrial system.

- Factual information backed by scientific research proves that appropriately treated reused water meets all necessary health guidelines for various uses including irrigation, cooling towers in power plants, and concrete mixing at construction sites among others.

FAQs in Relation to How Does Reverse Osmosis Play a Role in industrial Wastewater Treatment

How is reverse osmosis used to treat industrial wastewater?

Reverse osmosis purifies industrial wastewater by forcing it through a semi-permeable membrane. This process removes up to 99%+ of contaminants, including dissolved salts, particles, organics, and bacteria.

How is reverse osmosis useful in industry?

In industries, reverse osmosis helps save costs by reducing water usage and improves local water quality. It also aids in sustainable management of resources and promotes positive public relations through environmental stewardship through water reuse and recycling initiatives.

Want to learn more about the issues that tertiary reverse osmosis in industrial wastewater treatment can help your organization solve? Contact the water & wastewater treatment experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or reach out to us via email at customersupport@genesiswatertech.com to discuss your specific application.