Genesis Water Technologies Engages in PFAS Challenge with Innovative Treatment Solution

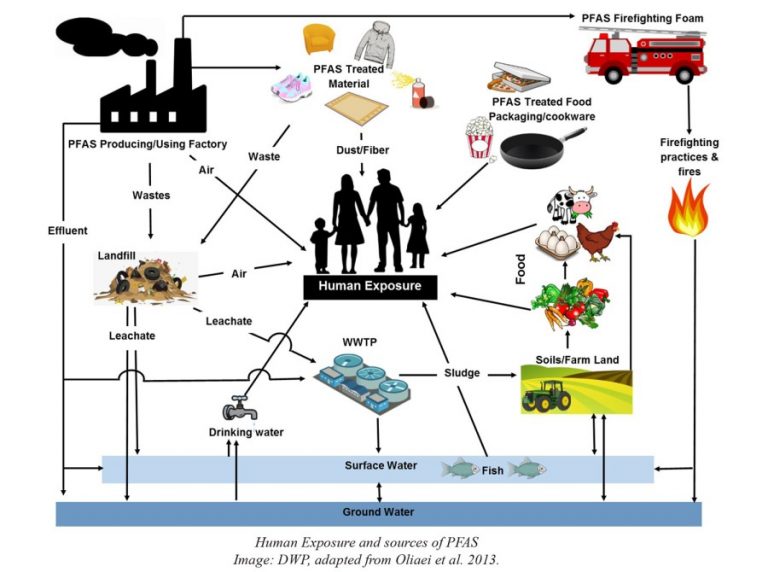

PFAS – Per and Polyfluoroalkyl substances is a family of synthetic industrial compounds that has been used in everything from cleaning products to waxes, water repellents to consumer products and firefighting foams. This family of nicknamed, “forever chemicals” has infiltrated water supplies across the world. The effects of exposure to these chemicals are only starting to become uncovered.

At this point, based on validated published research by the Environmental Working Group (EWG), a non-profit, non-partisan organization dedicated to environmental and human health, there are over 1398 sites in 49 states across the USA with PFAS contaminated water supplies.

The latest update of an interactive map by EWG and the Social Science Environmental Health Research Institute, at Northeastern University, documents publicly known PFAS pollution in public water systems, military bases, airports, industrial plants, landfill dumps, and firefighter training sites across the US.

In addition, it is not a surprise that 60,000 residents of Wilmington, NC and cities in Michigan, New Jersey, and New York to name a few, have been exposed to multiple harmful emerging contaminants of the PFAS family of chemicals in drinking water. These emerging contaminants are a byproduct of the expansion of manufacturing over the years. This family of compounds are believed to have contributed to forms of cancer within residents of these regions over several decades.

A Proposed Solution

One company has proposed a innovative solution to this problem, ultimately saving lives, and optimizing treatment costs. Genesis Water Technologies, a leader in specialized solutions for the global water treatment industry, has proposed a solution to the challenge plaguing these affected areas that has not been dealt with optimally. This specialized treatment solution integrates Advanced Oxidation prior to the current approach of granular activated carbon, resins, or membrane technology to reduce operating costs and meet the ever changing regulatory limits on emerging contaminants such as PFAS.

Innovative Advanced Oxidation Systems designed, engineered and supplied by Genesis Water Technologies (GWT) provide a cost-efficient solution to treat problematic pollutants in both drinking water and wastewater. These systems are a part of a specialized treatment process that can treat GenX, PFAS and other recalcitrant contaminants in water. More importantly, it’s a means to take a step forward in the right direction for the areas across the US and around the world that are suffering similar issues. After all, clean water should be a right, not a privilege.

By integrating an Advanced Oxidation System, GWT can neutralize or remove the toxic contaminants in the tainted water source. These modular systems are adaptable to both industrial and small/midsize municipal water treatment applications.

Genesis Water Technologies designs these innovative systems utilizing a specific integration of our patent pending specialized electrochemical processes including EOX. In this EOX process, we are able to create an abundance of extremely reactive oxygen species and hydroxyl radicals that can destroy a wide range of pathogens and emerging contaminants in the tainted drinking water or wastewater source that can be further treated by conventional granular activated carbon polishing filter systems or specific resin systems.

What is GenX?

GenX is a member of a group of man-made compounds called Per- and Polyfluoroalkyl substances (PFASs). These chemicals consist of carbon-fluorine bonds that have been used in a wide range of industrial applications and tend to resist decomposition in the environment.

GenX itself is a processing aid used to make high-performance polymers used in a variety of applications including cell phones, laptops, and non-stick cookware among other applications.

Dupont, which later spun Chemours off, began making GenX in 2009 after agreeing to a consent order with the EPA to replace PFOA, a harmful substance also known as C8. At the time, the company said GenX has “favorable toxicological profile” and is easier for humans to eliminate than C8. It was only during a meeting with Wilmington, NC areas officials that it was revealed the chemical was also created as a byproduct of a vinyl ether process occurring at the Wilmington, NC area plant.

There are no federal limits established yet for the PFAS family of chemicals, as it is an emerging contaminant. However, state regulations are changing rapidly as its effects on the environment and human health trigger stricter regulations. For instance, the N.C. Department of Health and Human Services has set a health goal of 140 parts per million currently and other states are instituting stricter regulations.

So where do we go from here?

Through the incorporation of Genesis Water Technologies specialized technologies, we propose a highly effective path to treating GenX and PFAS in water as a primary technology before conventional carbon absorption to reduce these chemicals. This is accomplished by using the highly effective hydroxyl radical molecule to effectively treat not only the prior mentioned chemicals, but additional emerging contaminants in drinking water and industrial wastewater applications. This solution also requires a minimal footprint, while being cost-efficient to its operator.

Genesis Water Technologies is bringing forth a solution that can assist in this dealing with these PFAS issues. It is one of our goals, to educate the public and industry alike on the benefits provided by specialized Advanced Oxidation. Our goal is to serve all three parties at hand: the citizens of the region, the municipalities/govt agencies, and the manufacturing organization. It is our intention, to restore the reputation of the manufacturing organizations by instituting a public integration that will serve all parties listed above.

Cities and towns across the US, deserve a water treatment solution to solve the threats posed by emerging contaminants, and that solution integrates specialized Advanced Oxidation (EOX).

At Genesis Water Technologies we stand behind the belief that clean water is a right, rather than a privilege. Each day, we strive to use innovation to meet the water needs of the world. We believe that serving our clients provides benefits to our society.

Do you have any questions about the Advanced Oxidation Process (EOX) for PFAS and recalcitrant contamination remediation that were not covered here in this article? Contact the water treatment experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or feel free to reach out to us via email at customersupport@genesiswatertech.com to discuss your particular industrial or municipal treatment application.

Application Case Study:

Challenge:

A water utility in NY was evaluating treatment processes to handle PFAS contamination of their water source. They were currently using a conventional activated carbon system, but they had issues relating to the operational cost of the carbon and wanted to optimize the treatment process.

Solution:

Genesis Water Technologies conducted multiple bench scale tests on the water streams.

These bench tests included the utilizing of our patent pending specialized advanced oxidation system process (EOX) with a post carbon polishing filtration process.

GWT tested several different treatment reaction intervals & power intervals, as well as post carbon polishing reaction column times to assess the results.

Below, is a chart indicating the results of this drinking water testing as well as testing with an industrial client (These are labeled Drinking A and Industrial B):

Client Type | Before Testing | After Testing (EOX/ACarbon) | Removal Percentage (Post EOX) | Removal Percentage (Post A. Carbon) |

Drinking A | 150 ppt | 1.5 ppt | 95.00% PFDA | 99.00% |

Drinking A | 150 ppt | 1.5 ppt | 95.00% PFNA | 99.00% |

Drinking A | 150 ppt | 1.5 ppt | 90.00% PFHPA | 99.00% |

Drinking A | 150 ppt | 1.5 ppt | 95.00% PFOA | 99.00% |

Indust. Client B | 100 mg/l | 1 mg/l | 92.00% PFDA | 99.00% |

Indust. Client B | 100 mg/l | 1 mg/l | 92.00% PFNA | 99.00% |

Indust. Client B | 100 mg/l | 2 mg/l | 90.00% PFHPA | 98.00% |

Indust. Client B | 100 mg/l | 1.5 mg/l | 91.00% PFOA | 98.50% |