Cost Benefits of Process Water Disinfection via UV Light Sterilizer Technology

Water is a substance that has many unique properties unlike any other fluid in the world. It is certainly a vital component of the survival of organic life, but it is also extraordinarily useful in industrial, municipal, and commercial processes. Process water makes up a significant portion of water use in the commercial and industrial sectors and depending on the industry and site, can be used in high quantities. Of course, the water that is used needs to be clean and clear to prevent any product contamination or effects on equipment. However, the quality of water can also vary from application to application. Water from natural sources, will contain levels of dissolved solids and minerals, as well as organic material and microbial organisms such as bacteria or protozoa. Even water sourced from municipal water treatment facilities can still contain some level of contamination.Therefore, UV light sterilizer technology deserves to be evaluated to be used for process water disinfection within industry.

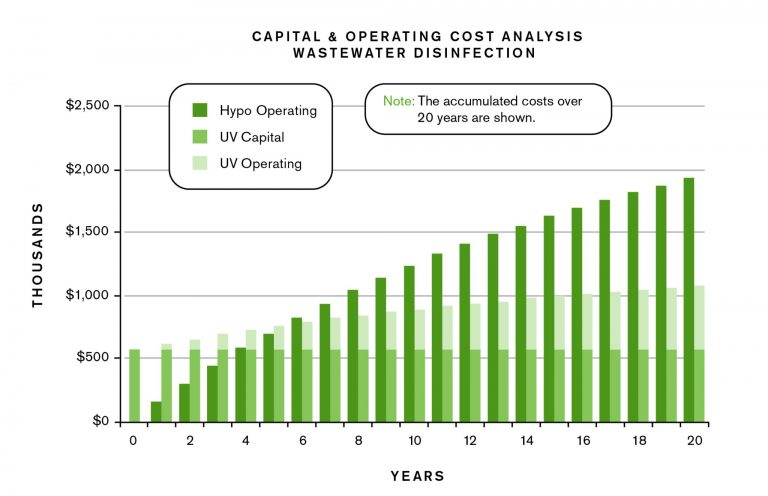

For the sake of the productivity and quality of products as well as the proper upkeep of process equipment, treating process water prior to use is very beneficial, if not vital. One step in treating process water is often disinfection, which leaves microbes present in the solution incapable of reproducing. There are several chemical options for disinfection, however, ultraviolet technology can provide several key cost benefits for on site treatment systems.

No chemicals

UV sterilizer technology is an entirely chemical-free system. Chlorine disinfection systems are some of the most commonly used and well known disinfection systems, but they have a few downsides with regards to process water treatment.

Disinfectant chemicals are hazardous additives. To ensure the safety of any operators and other staff, measures need to be taken to transport, store, and handle these additives. Some chemicals like ozone and chlorine dioxide need to be generated on site for use and can require extra equipment and power to do so. Other chemicals need proper storage tanks and distribution systems, plus any safety equipment and procedures for organization personnel.

Chemical disinfectants also tend to form disinfection byproducts in the presence of organics in a water source which can be hazardous. Disinfection residuals are good for water that goes through extensive distribution and storage to prevent any further contamination, but for process water they could potentially have a negatively impact on the product or process equipment.

UV sterilizer technology has none of these issues. There are no chemicals to store or generate, and because UV disinfection is a wholly physical process, there are typically no byproducts or residuals to affect product quality or process systems when the water is used.

Simplicity

You can list the components of an ultraviolet disinfection system on one hand: UV lamps, reactor chamber, sensors, electrical equipment, and control system. Chemical systems also need storage and dosing equipment, and in some cases, namely for chlorination systems, dechlorination equipment. Therefore, simple designs also mean easier operation for UV sterilizer systems. An easy to use system, needs fewer personnel for operation and maintenance and those personnel do not need to be as highly qualified. Maintenance primarily, includes cleaning fouled lamp sleeves and replacing UV lamps when they are past their useful life.

Time

This entire system is based around the properties of light radiation, and if there is one thing everyone knows about light penetration; it is fast. Even travelling through a medium like water, it takes next to no time for the UV radiation to reach the target pathogens from the ultraviolet lamps if the water is properly prefiltered. Chemical disinfectants need a few minutes to properly mix into the solution to cover the full volume. For comparison, disinfection of similar volumes of contaminated water with proper dosing can take chlorine up to 30 minutes to treat fully while a UV light sterilizer can take less than 5 minutes. Process water needs to be readily available, therefore, for facilities that treat water on site for use in production, reaction time can be critical to prevent production slowdowns. A UV light sterilizer can reduce disinfection treatment time significantly to obtain treated water which is ready for use in minutes.

Do you want to learn more about the cost benefits of a UV light sterilizer for your specific process water disinfection application? Contact the water experts at Genesis Water Technologies, Inc. at 1-877-267-3699 or reach out to us via email at customersupport@genesiswatertech.com to discuss your specific process water application.