Seawater Purification Methods Comparison: Best Choices

Are you trying to figure out the best seawater purification methods to recommend to a client?

It’s a big responsibility with a lot to consider.

Every project has different needs, but understanding the pros and cons of the available seawater purification methods is a great place to start.

Seawater purification methods are important, especially with growing global water scarcity issues. Finding reliable and sustainable drinking water solutions is critical.

Let’s examine some of the most common seawater purification methods, comparing their pros, cons, and ideal use cases.

Table of Contents:

- Commonly Used Seawater Purification Methods

- Key Considerations When Choosing the Best Method

- Comparing the Seawater Purification Methods

- FAQs about Seawater Purification Methods

- Conclusion

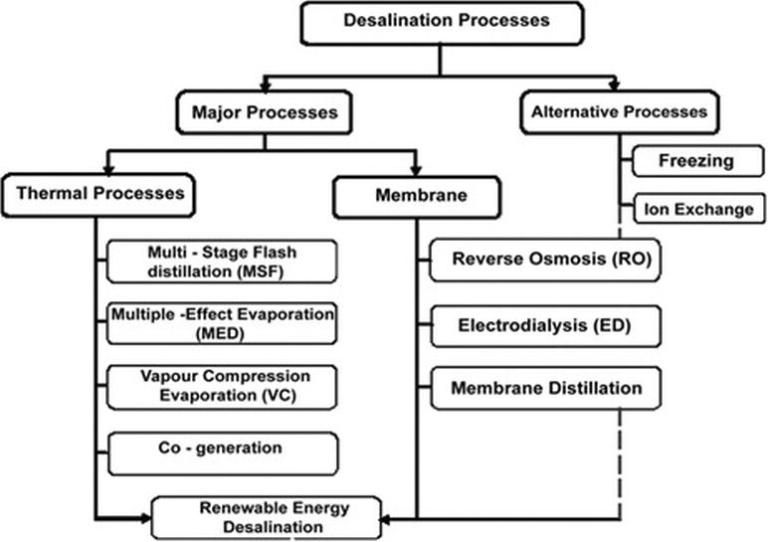

Commonly Used Seawater Purification Methods

The need for efficient seawater desalination technologies is always increasing.

To choose the right process, we need to evaluate the advantages and disadvantages of each method.

Thermal Desalination (MSF and MED)

Thermal desalination methods, mainly Multi-Stage Flash Distillation (MSF) and Multi-Effect Distillation (MED), had been industry standards for decades.

They mimic the natural water cycle but on a much larger scale to generate fresh water.

Both MSF and MED heat seawater to produce steam. This steam is then captured and condensed, leaving salt and impurities behind.

MSF uses a series of flash chambers at decreasing pressure. This causes the seawater to rapidly evaporate.

MED uses a series of evaporation chambers called “effects.” Steam produced in one effect heats the seawater in the next, increasing energy efficiency.

Although these techniques are reliable, they use a lot of energy and have higher associated operating costs. They also require specialized materials and skilled labor to operate.

Reverse Osmosis (RO)

Reverse Osmosis (RO) desalination is one of the leading seawater purification methods because of its energy efficiency and reliable water quality.

According to a 2019 study, over 16,000 desalination plants operate across 177 countries.

These membrane desalination plants generate roughly 95 million m3/day of freshwater.

Seawater desalination systems, especially those that use RO, are critical for addressing freshwater resources around the globe.

This method pushes seawater through a semi-permeable membrane, which acts as an ultra fine filter, allowing only water molecules to pass while blocking salts and other impurities.

Reverse osmosis plants have competitive initial costs and membrane maintenance needs.

Additionally, the water produced uses lower energy consumption compared to thermal distillation methods which has made it popular.

Other Emerging Technologies

While MSF, MED, and RO are some of the most common seawater purification methods, several emerging solutions show great promise for some brackish water sources:

- Forward Osmosis (FO)

- Electrodialysis (ED)

- Membrane Distillation (MD)

- Adsorption Desalination (AD)

These technologies use different principles for producing fresh water. Some focus on using waste heat sources or innovative materials.

This focus often translates into potential cost reductions and environmental benefits compared to established technologies.

However, because these are newer techniques, experts are still evaluating long-term performance, scalability, and cost-effectiveness.

Key Considerations When Choosing Seawater Purification Methods

Choosing seawater purification methods goes beyond simply comparing technologies.

To determine which one is optimal, there are several crucial factors impacting this important choice.

Water Quality

The quality of the source water plays a big role in determining the suitable desalination process.

High amounts of suspended solids, organic matter, or other contaminants may require extensive pre-treatment steps.

Pretreatment steps vary in complexity and cost depending on the specific water source.

Energy Consumption and Cost

Energy usage is a driving force in determining operational costs.

Desalination is an energy-intensive process, and minimizing this is essential for affordability and sustainability.

Reverse Osmosis has significantly reduced energy requirements, especially compared to thermal processes.

The optimization of membrane technology, pressure recovery devices, and energy-efficient pumps continues to reduce the operational expenses of this treatment process.

In fact, the power required to produce a liter of water to be treated is about the cost of running a simple google search on your computer.

Environmental Impact

Environmental impact is a vital consideration in any seawater purification method. Brine disposal, energy use, and the carbon footprint are key areas of focus.

Brine, the highly concentrated salt water leftover after desalination, can significantly harm marine life if not managed correctly.

Researchers are actively looking at ways to minimize the environmental impact, and in fact several recent research studies have indicated that sustainably designed discharge systems mitigate these issues profoundly.

Using hybrid energy sources to power desalination plants, exploring suitable brine management techniques, such as turning it into useful byproducts, optimizing discharge systems and developing eco-friendlier membrane materials show a promising future.

Maintenance and Operation

Every seawater purification method comes with its own set of needs when it comes to ongoing maintenance and operation to produce high-quality water.

For example, thermal-based desalination technologies often require specialist knowledge due to the high temperatures and pressures involved in removed dissolved solids.

Reverse osmosis systems require optimized pretreatment to prevent scaling and membrane fouling, which ensures successful performance.

Seawater Purification Methods Comparison

When choosing a system for seawater purification, creating a table can be beneficial.

It allows you to visually see how they compare across crucial criteria, including cost, pros, cons, desalination applications, water quality, and energy use:

| Method | Cost | Pros | Cons | Application | Water Quality | Energy Use |

|---|---|---|---|---|---|---|

| Multi-Stage Flash Distillation (MSF) | High | Proven, reliable technology; Handles high salinity water | Energy-intensive; Requires large footprint for installation | Large-scale desalination; Areas with high energy availability | High purity; Suitable for drinking and industrial | High (8–16 kWh/m3) |

| Multi-Effect Distillation (MED) | High | More energy-efficient than MSF; Lower operating temperature | Complex operation and maintenance; Sensitive to feed water quality | Medium to large-scale desalination; Coupling with cogeneration plants | High purity; Suitable for drinking and industrial | Moderate (3.5–7 kWh/m3) |

| Reverse Osmosis (RO) | Moderate | Lower energy consumption compared to thermal methods; Smaller footprint | Membrane fouling; Requires pre-treatment | Wide range of applications: municipal, industrial, brackish and seawater | High purity; Dependent on pre-treatment | Low (3–6 kWh/m3) |

| Forward Osmosis (FO) | Developing | Lower fouling potential than RO; Potential for lower energy consumption | Slower process; Requires draw solution recovery | Developing for desalination; Wastewater treatment; Concentration applications | Variable, depends on membrane and draw solution | Potentially low, still under research |

| Electrodialysis (ED) | Moderate | Suitable for brackish water; Lower energy consumption than RO for specific applications | Limited salinity range; Fouling can impact efficiency | Brackish water desalination; Water softening; Industrial applications | Moderate purity; Can be affected by feed water composition | Low to moderate (depends on salinity) |

| Membrane Distillation (MD) | Developing | Low operating temperature and pressure; High salt rejection | Lower fluxes than RO; Membrane wetting can be a challenge | Desalination of high-salinity brines; Water recovery from industrial processes | High purity; Less affected by feed water variations | Potentially low, dependent on heat source |

| Adsorption Desalination (AD) | Developing | Uses waste heat; Environmentally friendly; Low energy consumption | Slower process; Lower production capacity | Small to medium scale applications; Remote areas with waste heat sources | High purity; Potential for selective salt removal | Very low (less than 1 kWh/m3) |

Real-world Application: Sorek Desalination Plant

The Sorek desalination plant in Israel is a great example of how choosing the right desalination technology can offer solutions to address water scarcity.

This facility, which uses advanced reverse osmosis, and is one of the world’s largest seawater desalination plants of its kind. It supplies nearly 20% of Israel’s domestic water needs.

This highlights how forward-thinking investment in this technology combats growing concerns regarding freshwater availability.

FAQs about Seawater Purification Methods

What would be the best method to purify seawater?

While there’s no one-size-fits-all solution, reverse osmosis (RO) has become the leading seawater purification method globally because it’s energy efficient.

That said, factors like energy costs, desired water quality, and the scale of the operation require careful analysis.

Other desalination technologies are great alternatives but most depend on the situation. Always check requirements before making your recommendation on which to use to generate potable water or process water.

What is the difference between MSF and Med?

Both MSF (Multi-Stage Flash Distillation) and MED (Multi-Effect Distillation) are thermal desalination processes that work by evaporating and then condensing seawater.

However, they use different methods to do this. The main difference, MSF uses a series of chambers with decreasing pressures to rapidly flash-evaporate water.

MED uses a sequence of effects, where steam from one heats the next, utilizing heat more efficiently.

This setup makes MED slightly more energy-efficient than MSF. However, it also makes it more operationally complex.

What is the best separation technique for the desalination of seawater?

When making recommendations for the best separation technique for seawater desalination, consider all factors for your project before deciding.

Based on current technologies, reverse osmosis (RO) is the most effective technique for desalinating large volumes of water worldwide.

This is because of its balance of water quality, energy efficiency, and overall cost optimization.

What is the most effective desalination method?

This depends on your definition of “effective.” If cost-effectiveness and energy use are your primary metrics, then reverse osmosis is usually the best choice.

However, other promising desalination technologies continue to emerge.

Some of these have a low environmental impact or specific advantages, such as utilizing waste heat or having a compact design. This is driving future innovation in the water industry.

Conclusion

Selecting the optimal seawater purification method is crucial for addressing water scarcity challenges effectively for both industry and the human population.

While reverse osmosis (RO) has emerged as a leading technology due to its energy efficiency and versatility, each project’s unique requirements demand careful consideration of all available options.

From thermal desalination processes like MSF and MED to emerging technologies such as forward osmosis and adsorption desalination, seawater purification methods continue to evolve.

By weighing factors such as water quality, energy consumption, environmental impact, and maintenance needs, you can make an informed decision that best suits your specific project goals.

Remember, the success of large-scale desalination projects like the Sorek plant in Israel demonstrates the transformative potential of well-chosen seawater purification methods in combating water scarcity.

Don’t let water scarcity hold your project back. Take the first step towards a sustainable water future today.

Consult with our team of water treatment experts at Genesis Water Technologies to analyze your unique needs and identify the most effective seawater purification methods for your situation.

Together, we can turn seawater into a reliable freshwater resource, ensuring a stable water supply for generations to come.

Contact Genesis Water Technologies today at +1 321 280 2742 or via email at customersupport@genesiswatertech.com to start your journey towards water security and sustainability!