How to Choose The Most Appropriate Biological Wastewater Treatment Process Based On Application

There is different discharge restrictions for wastewater produced by different sectors and industries. Treatment systems need to be designed around each individual application in order to specifically target and treat the pollutants produced by them. This is why it is important to choose the correct biological wastewater treatment process for secondary stage wastewater treatment.

When choosing treatment methods for wastewater systems, there are many options to choose from within the different treatment stages. Secondary stages typically consist of biological wastewater treatment systems, and those, in particular, have several different options. Careful considerations of multiple aspects need to be made to choose the most optimal solution for a particular application.

At the core of the biological wastewater treatment process, there are three general considerations and two that are specific to biological treatment.

The general considerations include :

Occupied area or how much land the system will occupy on site;

Construction costs, how much money will be required to build the system;

Operating costs, the costs associated with the day to day use of the system

The specific considerations are the hydraulic retention time (HRT) and sludge retention time (SRT). HRT refers to how long the effluent is exposed to the process. SRT however, is the length of time that a unit of sludge (or other bio media) is active within the reactor.

Treatment selection and design of biological wastewater treatment systems take all five of those criteria (and others) into account. Often during decision-making processes, weight values are given to each criterion and then points are given to each method for each of those criteria (often by way of a ranking system). The points are multiplied by the weights and the results are used to compare each option numerically. The weighting system is usually subject to change based on what criteria a company or municipal organization deems more important, so we won’t go into that in this article.

Instead, we’ll rank the options in comparison to one another under the assumption that all organic loads and flow rates are the same for each possible system.

We will discuss four biological wastewater treatment processes and the specific advantages and disadvantages of each below.

Four Possible Biological Processes:

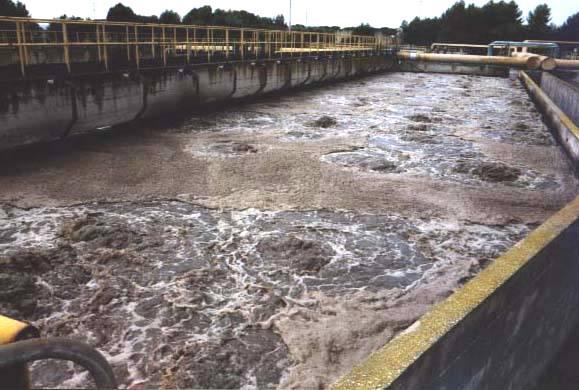

Activated Sludge Process (ASP)

A suspended solids system that aerates a loose biological media and is then pumped to a clarifying tank to settle. Sludge from the clarifier is recirculated back into the reactor, called return activated sludge.

Occupied Area: Second largest HRT: Second lowest, 4-10 hours

Construction Costs: Second highest SRT: Lowest

Operational Costs: Low

Sequencing Batch Reactor (SBR)

A version of an ASP that does not have a separate clarifying tank. Instead, after a sufficiently long retention time, the solution is allowed to settle and the resulting supernatant is pumped to tertiary treatment.

Occupied Area: Second smallest HRT: Second highest, 6-12 hours

Construction Costs: Second lowest SRT: Similar to OD

Operational Costs: Low

Oxidation Ditch (OD)

Another version of ASP that moves the effluent around an elliptical or circular channel for an extended aeration cycle.

Occupied Area: Largest HRT: Highest, 12-24 hours

Construction Costs: Highest SRT: Similar to SBR

Operational Costs: Low

Moving Bed Biofilm Reactor (MBBR)

A fixed film system that uses a biofilm that has adhered to small specialized carriers that are moved about the reactor by aeration bubbles. Like the ASP, MBBR is followed by a clarification step.

Occupied Area: Smallest HRT: Lowest, 1-5 hours

Construction Costs: Lowest SRT: Highest

Operational Costs: Low

Process | Type | Advantages | Disadvantages |

ASP | Suspended Solid |

|

|

SBR | Suspended Solid |

|

|

Ox. Ditch | Suspended Solid |

|

|

MBBR | Dynamic Fixed Film |

|

|

Each of these treatment methods has a variety of pros and cons that can make them good or bad for a particular application. All four are low cost in terms of operation, but construction costs were higher for reactors that required more land area, the oxidation ditch being the highest in that regard. As for the retention times, MBBR was better on both accounts, having higher sludge retention without sacrificing hydraulic retention like the SBR and oxidation ditch methods. MBBR is a very strong contender for consideration, especially if the unit comes from a company with well-designed carrier media. In many cases, comparing reduction rates of an MBBR unit with lower active surface area media with that of other treatments can show MBBR with lower removal efficiency. Therefore, MBBR can also be considered as an add-on process to be used with some form of activated sludge process to improve the treatment efficiency of the entire system.

What you see above are guidelines that may be considered when making a decision on a biological wastewater treatment process. Inevitably, the manner in which deciding factors are weighted is entirely dependent on what the involved company feels is more important, and design companies can always provide more detailed information that can aid in decision making.

Do you need some assistance in deciding on a biological wastewater treatment process for your municipal or commercial/industrial wastewater treatment application?

Contact Genesis Water Technologies, Inc. at 1-877-267-3699 within the USA, reach out to our local offices worldwide or contact us via email at customersupport@genesiswatertech.com to speak with one of our knowledgeable specialists to discuss your application.